11 mins read

What Is The Purpose Of Construction Specifications? Exploring Their Importance

A construction project has many moving parts that must work together to succeed. To do so, each material, activity, and process needs to be planned to the smallest detail to ensure the project runs smoothly with no cost overruns or delays.

However, planning can only get you so far if it is not appropriately communicated to the right stakeholders. It is no secret that issues with communication in construction projects can account for a big percentage of time delays and cost overruns, which makes having detailed information available for everyone a priority. That is where construction specifications come into play.

Construction specs serve as powerful information hubs for project stakeholders, ensuring every detail is specified without room for misinterpretation or error. But what is the true value of specs?

This blog post provides a comprehensive definition of construction specifications, a list of key elements, and the different types of specs. We also review the value of specification tools, provide an explanation of the key benefits of specs in construction, and best practices for generating them successfully.

What Are Construction Specifications?

Construction specifications, also known as construction specs, are written documents that describe the scope and methods of work, materials, workmanship, permits, timelines, etc., for a project that will be placed under contract.

Specs are generated during the design phase and serve to connect the design and construction stages of the project to ensure no discrepancies occur between the initial idea and what actually is built. They are often handed over to contractors and subcontractors as part of the contract documentation to use as guidelines for carrying out their work. In some cases, subcontractors only receive the portion of the specs that relate to their scope of work instead of the entire document.

The general contractor also uses specs to define the schedule and organize the delivery of materials or equipment. The project owner might also use them once the project is completed to carry out inspections and evaluate the work.

Construction companies in North America mostly use the Construction Specifications Institute (CSI) MasterFormat to organize specs. CSI MasterFormat provides templates that organize the information in a list of Divisions and Sections to make it easier to find. In the UK, a popular classification standard is the Uniclass 2015 from the NBS, which uses interconnected tables to classify information.

Who Generates Construction Specifications

Construction specs are usually technical documents generated by architects, engineers, and other professionals with the necessary expertise to gather the information. The documents are usually put together in a digital or paper format called a “spec book” and used throughout the entire project as guidelines for the work to be completed.

In bigger or more complex projects, the owner might hire a spec writer to carry out the work. These professionals are qualified to take what they know from the project and put it into a concise and understandable format that anyone can understand. Spec writers can work in-house for an architectural firm or as independent consultants with the help of professional construction specification tools.

Drawings vs. Specifications

In many cases, the words construction drawings and specifications are used interchangeably. However, while both are valuable construction documents, they differ in format and scope.

Drawings are visual representations of the building project. They tell you where each element fits and how it should look. Specs, on the other hand, are written documents that describe the project in terms of materials, regulatory requirements, pricing, workmanship, and more. They go beyond just telling you where something goes to how to install it, the material, the color, and much more.

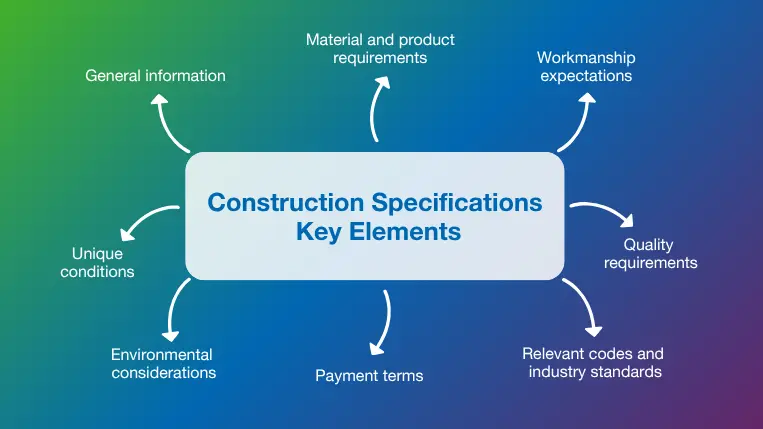

Construction Specifications: Key Elements

Construction specifications can vary depending on the project elements being described, the standards followed, and the preferences of the project owner and other stakeholders. However, most well-written construction specs include a few key elements.

General information

Specifications in construction should always include some basic information to let the reader know the purpose, subject, and scope of the document. The general requirements section might also include information on roles and responsibilities, as well as the submittal procedures for samples, drawings, or other documentation requirements, when applicable.

Material and product requirements

This section includes a detailed description of the materials and products to be used during construction. Depending on the type of specification, material manufacturers, material grades, performance standards, and units of measure (UoM) might also be found in this part of the spec. These requirements, in conjunction with the bill of quantities (BoQ), provide essential information on the overall scope and cost of a project.

Workmanship expectations

Unlike construction drawings presenting only the finished floorplan, feature, or detail, construction and building specifications take a deeper dive into workmanship requirements and installation methods. Workmanship requirements often reference industry standards for tolerance, finish, and consistency to ensure all work meets client expectations. Installation instructions support this effort by ensuring the methods used can produce the desired results.

Quality requirements

Measurement, test, and inspection requirements allow project teams to determine through objective evidence whether each material or project element is acceptable. Important items often call for 100% inspection, while less important features and materials are sampled to provide more confidence in their level of quality.

Relevant codes and industry standards

Industry standards and codes can be useful in defining consistent quality standards. Including relevant codes in construction project specifications also makes it easier to convey important safety and access requirements in a manner that is easy to understand. Adherence to codes protects both contractors and clients from legal consequences, while ensuring finished buildings and structures are safe and durable.

Payment terms

Payment terms outline the timing and method of compensation for contractors and subcontractors. This section covers the payment schedule, invoicing requirements, and any penalties for delays or non-compliance.

Change orders are also addressed to clarify how modifications to the project scope, budget, or timeline will be handled. It specifies how change orders must be documented, reviewed, and approved, as well as how associated cost and schedule impacts will be managed.

Environmental considerations

Requirements for energy efficiency, waste management, reusability, and embodied carbon are becoming important elements of specs in construction, as the industry continues to move toward sustainable building practices. Detailed environmental requirements are essential for builders and architects striving for LEED or BREAM certification, since each individual specification contributes to the overall rating of the building or structure.

Unique conditions

Specifications, terms, and conditions that do not fit neatly into other areas of construction specifications are known as special provisions. The topics covered under this category include unique construction methods requiring special tools and equipment, noteworthy site conditions, and instructions for coordinating with other contractors or specialists. Special provisions are useful for projects that require a high level of customization, or follow practices that are not standard or common in the construction industry.

Types of Construction Specifications

Different types of construction specifications are used for different projects. For informational purposes, we will explain these types as separate things, but in most cases, projects use more than one type for distinctive design elements. Let’s explore them in detail below.

- Prescriptive specifications: Also known as descriptive specifications, they outline the exact materials, installation methods, workmanship quality requirements, and other elements of the project. They are the most detailed type of specs and are widely used in projects where the owner wants to ensure the designer’s vision is executed exactly as intended. This approach reduces the risk of misunderstandings or misinterpretations from the contractor, as everything is outlined from the beginning. Prescriptive specifications also include details about building codes and safety standards that contractors must follow.

- Performance specifications: This type of specification describes the operational requirements of the finished project without providing detailed instructions on how to achieve them. It is up to the contractor to analyze which materials and methods are better to complete the work as long as the final product meets the requirements. The main advantage of this spec type is that it allows the contractor to leverage their expertise and implement innovative technologies or cost-effective solutions that the client may be unaware of. However, it also leaves room for varied interpretations of the project requirements, which can lead to costly reworks, which is why they are mainly used for straightforward and not-too-complex projects.

- Proprietary specifications: This type of spec is used when a specific brand, model, or other defined detail needs to be used to carry out the work. Historically, proprietary specs have been used mostly in renovation projects where details about specific materials are needed to ensure the new construction matches what is already in place. However, they have gained popularity in recent years as the need to specify granular details increases. In fact, most manufacturers include a spec sheet with the materials or product purchases to include in the specifications. Proprietary specifications can be closed, with no substitutions allowed, or opened, allowing for other alternatives.

- Reference specifications: This spec type condenses and summarizes key information by referring to other standards, codes, and requirements rather than including all information in detail. This format can improve quality and consistency by referencing well-known and established standards such as ISO, ASTM, and relevant building codes that are familiar to contractors, rather than rewriting the text in a way that is open for interpretation and time-consuming to create and interpret. Specification writers leveraging this option should always review the latest codes and standards to ensure they are still aligned with the information and quality levels they want to communicate.

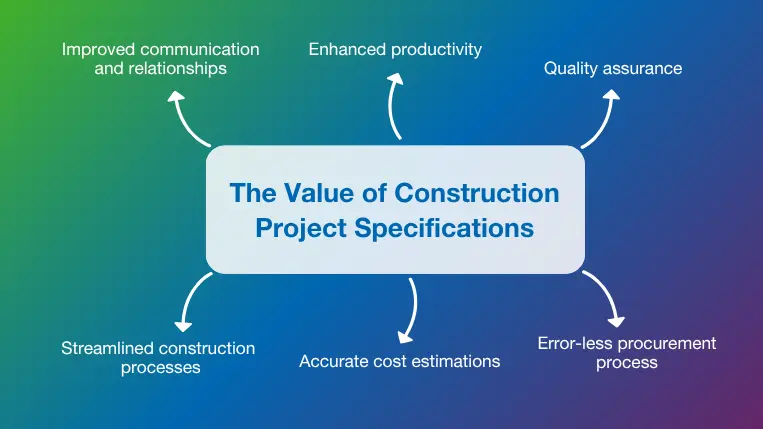

The Value of Construction Project Specifications

Disputes between contractors and clients are common in construction projects. Most of these disputes happen due to misunderstandings or missing specifications about how the work should be carried out. Some of these discrepancies can lead to accidents or failures when the building is already being operated, making using specifications more critical than ever.

Experts in the field highlight specifications as one of the key elements driving improvement and innovation in construction projects. This is not surprising, as successful construction projects require as much detail as possible.

With that in mind, let’s explore some of the key benefits of specs in construction.

Improved communication and relationships

Probably one of the biggest benefits of using specifications in construction projects is the fact that they boost communication and ensure good relationships between contractors and the project owner. Specs detail all the necessary information from the design to ensure the construction process is carried out according to plan. This prevents misunderstandings that can generate disputes and relationship challenges between parties as expectations are set from the get-go.

Enhanced productivity

It is not a secret that construction productivity has always been challenging for the industry. With the rise of modern construction management software with multiple collaboration features, this challenge has been more or less tackled. However, collaboration technology can only get you so far without the right information. Building specifications ensure all the information is delivered to contractors and available in a digital format so they can know exactly what to do and expect from each work. This avoids delays due to misunderstandings and allows for better task planning, significantly enhancing productivity.

Quality assurance

As mentioned, specs in construction projects offer detailed information about all aspects of a build, from materials, colors, and finishes to safety codes and standards it needs to follow. This sets a clear quality standard for the work to be completed, ensuring no issues occur that can interfere with the expected outcomes. That is why specs are also used as guidelines to cross-check the work that is completed, as the information they provide has been carefully put together by a team of experts.

Error-less procurement process

The details provided by construction specs can improve the construction procurement process. Information about what materials, finishes, equipment, etc., they must procure is available from the early planning stages. This ensures an error-free process that prevents procurement cost overruns. Plus, it allows for efficient planning for the delivery of materials, as timelines are also specified in the spec’s documents.

Accurate cost estimations

The construction cost estimation process relies on specifications to provide details about materials and labor requirements. Detailed specs can significantly improve the accuracy of the estimates, which in turn avoids cost overruns or delays that can affect the project’s profitability.

Streamlined construction processes

The information contained in construction specs acts as an all-inclusive guide to help contractors, subcontractors, and procurement teams complete their tasks with limited questions or oversight. This allows these experts to plan their time effectively, optimize their resource allocation, and stick to predefined project timelines. Clear material and installation guidelines help teams get the job done right the first time. Well-written specs also minimize the need for change orders that can halt progress and increase project costs.

How To Generate Successful Construction Specs

As you’ve learned by now, specs are fundamental to a project’s success, so they should be taken seriously. Many people might consider the process tedious and time-consuming. Luckily, this is not the case anymore, as innovative software solutions have been developed to make it faster and more efficient.

For example, RIB SpecLink, our platform for construction specifications, is a cloud-based solution that centralizes the spec writing process by offering all project teams access to contribute with specs while ensuring that spec experts control the final output. Plus, specs can be accessed from any browser-enabled device, ensuring full accessibility and collaboration across the entire project.

That said, specialized software can only take you so far if the process is not approached correctly. Below are some tips to help you ensure success!

Don’t be afraid to get specific

The best advice we can give you is not to be afraid of getting specific. Spend the necessary time ensuring that the project vision is accurately portrayed so that the rest of the project stakeholders can use it as a guideline for their work. Specialized software like RIB SpecLink offers advanced functions to identify conflicts and considerations to improve outcomes, reducing the risk of errors or omissions. Plus, the software has a 10+ year strategic relationship with the CSI, meaning all features are developed with their best practices in mind.

Follow the 5C’s framework

As mentioned earlier in the post, spec writing requires thoughtful planning, creative thinking, and the ability to present complex information in an understandable format. To do so, we recommend following the 5Cs of specification.

- Clear: Use clear language that is understandable for everyone in the project. Make sure all roles and responsibilities are clearly defined, all acronyms, abbreviations, and terminology are defined, all repetition has been removed, and all unnecessary legal jargon is removed, among other things.

- Concise: Write concisely. Avoid using wordy sentences that make reading the document more difficult. An active voice is recommended to make the content more specific and direct to the responsible parties.

- Complete: Check that the information is deep enough to add value. Concise does not mean incomplete!

- Correct: Make sure you cite updated standards and that the information is only mentioned once and in the correct place.

- Consistent: Keep consistency in terms of terminology, structure, and style. Everything should be easy to navigate and understand.

Offer training and accessibility

Project teams need to be able to access and understand construction specs to use them correctly. For example, an estimator needs to understand the different sections of the construction specifications to prepare for bidding. Likewise, the owner or project manager needs to be able to read the spec documents to confirm that the work complies with the specifications. That is why we recommend offering training to ensure everyone is familiar with the formats and the information contained to prevent any issues down the line.

But it does not stop with training. As mentioned, many stakeholders will need access to specs to reference the information contained in them. Therefore, it is of the utmost importance to provide full accessibility but in a controlled environment. Software like RIB SpecLink functions in the cloud, meaning anyone can access the documentation for any device with an internet connection. Plus, our platform allows collaborative document editing with the possibility to track any changes and ensure transparency for an efficient workflow.

Avoid document conflicts

Construction specifications complement drawings and other contract documents by providing more detailed information on the same building elements. For this reason, it is important to review related documents each time a new specification is created or updated, to ensure there is no conflicting information presented that might lead to confusion or errors during construction. The same review process applies to drawing changes that potentially impact related specifications.

Repetition within specifications is another practice to avoid, including requirements repeated within the same specification using slightly different wording, or drawing notes that repeat the same instructions or workmanship standards found in the specification. A lack of repetition throughout the documentation package also streamlines editing and review processes when changes are required.

Use consistent formatting

Standard formats and classification systems like Uniclass and CSI MasterFormat can be extremely useful for organizing the information within construction specifications clearly and logically, but when these systems are used, they must be used consistently. For example, it is unwise to format some sections according to CSI MasterFormat conventions, then follow Uniclass 2015 in other parts of the spec.

Formatting should be consistent across the entire project so that the specification library can be filed and organized in a way that makes the information readily accessible and searchable. Even when no industry standards for construction project specifications are utilized, consistent formatting helps to set expectations for users and allows them to find important information more quickly.

Consider the audience

Construction specifications are read by a wide range of stakeholders with varying levels of technical knowledge, including designers, architects, contractors, suppliers and owners. While it can be difficult to tailor specifications to multiple audiences at once, avoiding technical jargon unless it is necessary, keeping sentences brief and concise, and providing well-organized information helps to address the needs of multiple audiences simultaneously.

Providing definitions for technical terms is also useful, especially when new processes, material properties, or test methods are used for the first time and delays and confusion at the job site must be avoided. As legally binding elements of the construction contract, specifications should also be written with legal reviewers, regulatory bodies, and auditors in mind by making all material, workmanship, and approval requirements apparent throughout the specification.

Coordinate with key stakeholders

Cross-functional coordination is an important consideration when creating specifications in construction, since it is essential for all key stakeholders to be aligned on the contents. Architects, designers, contractors, and specialists each bring a unique perspective that ensures all audiences will understand the written requirements and instructions.

Cross-functional reviews allow any differences of opinion on materials, quality requirements, and referenced standards to be resolved early on to facilitate smoother procurement and building practices. Real-time collaboration during the spec writing process also helps to minimize grammatical errors and obsolete references that would require downstream spec changes if left uncorrected.

Keep specifications current

The importance of specifications in construction makes diligent review and approval cycles designed to ensure high-quality buildings and structures essential. Maintaining up-to-date specifications is a big part of this objective, since all information must be current for the design intent to match the results. This applies to material testing and safe handling practices, as well as performance and installation criteria.

Manufacturers frequently change or discontinue material and product offerings, so verifying availability is an important first step. Building codes, environmental regulations, and manufacturer instructions are also subject to frequent and unexpected changes, so this information must also be verified to ensure it remains current. Construction specification software linked to live material, product, and regulatory databases makes it easier to review specifications for currency quickly.

Set clear quality standards

Quality standards set benchmarks that ensure the finished project meets its goals and objectives for safety, durability, and aesthetic appeal. Clearly written quality standards also ensure a common understanding of specifications among stakeholders, without leaving room for ambiguity or debate. These standards might include destructive testing or precise measurement processes, or simply call for the visual inspection of key attributes. When specific measurements or tests are necessary, specifications should clearly define the processes and equipment that must be used, the proper format for recording information, and the success criteria defining passing and nonconforming results.

Ensure legal and regulatory compliance

Transferring a winning design into a well-constructed building or structure is the primary objective of specifications in construction, but spec writers should also pay close attention to legal and regulatory compliance to avoid potential fines, delays, or reputational damage. Many building codes and industry regulations were created to protect the safety of workers and building occupants, and this should be emphasized throughout the writing and review process. Requirements related to personal protective equipment (PPE), safe work practices, or emergency procedures should never be subjective.

Final Thoughts

As you learned throughout this post, specifications in construction play a crucial role in a project’s success. They ensure that all parties are clear about their scope of work and that healthy relationships can be built during the project lifecycle. They are also crucial in contract agreements, making them quite valuable for construction companies.

Mastering the process is a journey that requires continuous improvement and the involvement of all stakeholders to avoid misunderstandings or disconnections that affect the project. Following best practices and supporting your team with the right technology can significantly impact the process. Specialized software substantially cuts the time it takes to write specifications thanks to automation and features that make the process much easier and more efficient.

RIB SpecLink is a state-of-the-art spec software with years of experience in the industry and more than 25.000+ users. Our platform has collaboration at its core to ensure specs can be written and supported by the expertise of all project stakeholders. Our custom templates speed up editing, increasing productivity and lowering costs.

If you want to test these and a range of other innovative functionalities to take your specifications process to the next level, get a demo of RIB SpecLink today!

Most Recent

11 mins read

10 mins read

10 mins read

29 mins read

Blog Categories

Ebook