11 mins read

Understanding The Different Types Of Estimates In Construction

Construction cost estimation is the foundation upon which projects in the construction industry are created. These are careful computations that dictate timeframes, budgets, and the viability of the project; they are not just numbers. Construction estimates are essential at every stage of the project lifecycle, from the first idea to the last nail-driven home.

Note that there is a difference between cost estimation methods and types of cost estimation. These may be confusing, as there are many synonyms for the same concepts.

In this blog post, we will define types based on the level of accuracy implemented by the ASPE and methods as ways of estimating.

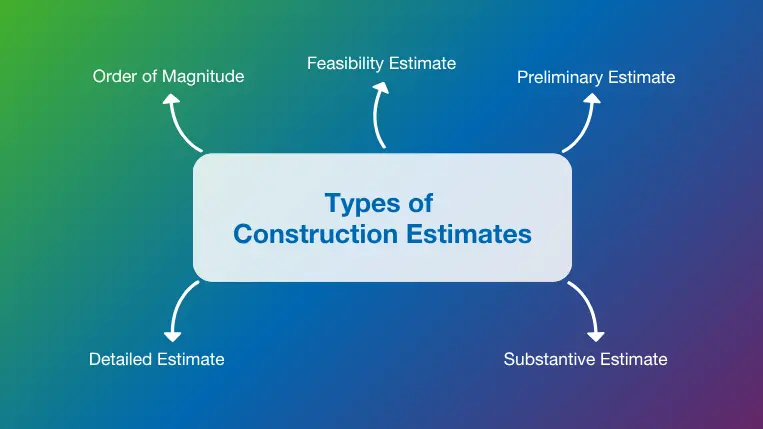

Types of Construction Estimates

It is customary to produce several cost estimates during the pre-design and design stages, since a precise estimate can only be made with a clearly specified project plan. The more defined your project is, the more accurate these estimations become.

Estimates are categorized using a five-level system by the American Society of Professional Estimators (ASPE), an organization that represents construction estimators. Level 1 is the least accurate and trustworthy, while Level 5 is the most accurate and reliable.

Strangely, some organizations, like the U.S. Department of Energy (through its construction estimating directive) and the Association for the Advancement of Cost Engineering (AACE), reverse the numbering and identify Level 1 as the most accurate estimate.

Below you will find the different types of construction estimates by levels of accuracy under the ASPE system:

1) Order of Magnitude

The order of magnitude estimate refers to a rough approximation made during the early phases of project conception. Here, giving a ballpark value is more important than accuracy. It assists interested parties in determining whether the project is worthwhile pursuing further and is financially feasible.

For example, for a $10 million construction project, this estimate would involve quickly assessing the major components of the project and making rough calculations based on past experience or industry norms. Taking all factors into account (for instance, reviewing documentation and researching industry norms), the order-of-magnitude estimate for a $10 million construction project might take approximately 8-11 hours, spread out over several days if necessary.

2) Feasibility Estimate

As the idea gains momentum, interested parties seek a more comprehensive evaluation of its viability. Now, for the feasibility estimate, consider several variables, including the site’s characteristics, applicable laws, and any potential dangers. This cost estimation method, though still wide in scope, helps stakeholders make well-informed decisions about moving on with the project. It gives a clearer sense of what lies ahead.

3) Preliminary Estimate

The preliminary estimate is based on a more defined project scope and provides owners with a basis to select the optimal alternative by weighing design features and configurations. To get funding, you may also show this estimate to lenders. It considers factors such as labor costs, supplies, and equipment. Although preliminary estimates are not as thorough as later-stage estimates, they do set the foundation for more in-depth planning and budgeting.

The AACE advises that the effort involved in this stage is 3 to 10 times that of a Level 1 (order-of-magnitude) estimate.

4) Substantive Estimate

The degree of detail in the estimates increases as the project progresses. The substantive construction estimate is a detailed examination that thoroughly reviews every aspect, taking no chances. Each step of the project is painstakingly examined and measured, down to the number of nails required to the price of licenses. This estimate serves as a trustworthy starting point for budgeting and as a reference point for monitoring project expenses as work progresses.

5) Detailed Estimate

The detailed estimate, which is the highest level of the estimating stages, is a thorough analysis of all project-related expenses. This estimate accounts for even the tiniest expenses. It calls for careful planning, exact calculations, and an in-depth understanding of the building procedures. Although it takes longer, the detailed estimate offers unmatched precision, ensuring that the project stays on schedule and within budget.

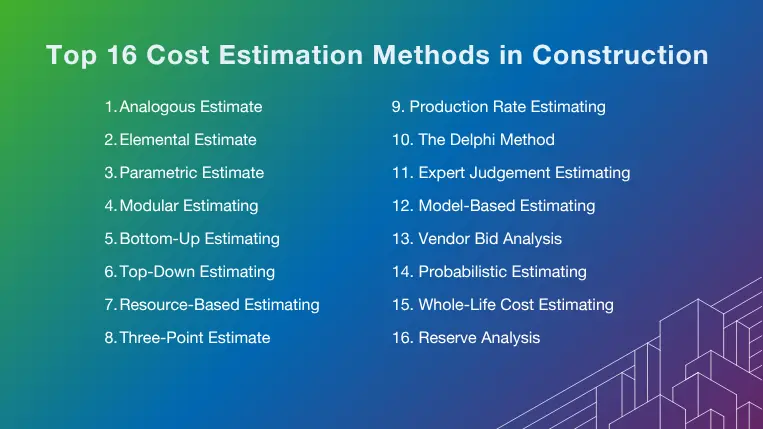

Top 16 Cost Estimation Methods in Construction

Cost estimation methods differ due to purpose, technology, and approach. From fast and easy (but less accurate) estimates to detailed ones that take more time and effort to compile, there is a variety of cost estimation methods in construction

Let’s explore the different ones below:

1) Analogous Estimate

Establishing analogies with previous projects is the basis of the analogous estimate method. Stakeholders can estimate the requirements based on past data by comparing the current project’s requirements with those of comparable completed initiatives. Although not entirely accurate, this approach provides a rapid and straightforward method for estimating expenditures at the project’s outset.

2) Elemental Estimate

The elemental cost estimate or elemental cost analysis is a more accurate method of analyzing construction costs, as it is based on detailed drawings and specifications. Often, clients employ the services of quantity surveyors who follow guidelines (as set out by various institutes), and this supports consistent and accurate costing. To ensure an accurate analysis, the building is divided into components (e.g., structural frames, facades, floor finishes, etc.), which are then broken down into smaller categories with quantities, multiplied by cost rates, to provide a total cost per component. Based on the area of the component, a cost per square meter can be quantified. All components are summed up to provide a total building and cost per square meter.

3) Parametric Estimate

One technique for cost estimating stands out from the others due to its effectiveness and adaptability: parametric cost estimation. Predicting a project’s cost using a collection of parameters or factors is known as parametric cost estimate. Parametric estimates leverage statistical correlations between past data and project parameters to create cost approximations, as opposed to comprehensive estimates, which mostly rely on itemized lists and exact computations. When comprehensive information may be scarce in the early phases of project planning, this approach is especially helpful.

Let’s delve into its key subpoints:

3.1) Plinth Area Cost Estimate

One of the other methods of cost estimation in determining the approximate building cost, this estimate covers the built-up area of the building. This is the entire area that the external dimensions of the building cover on the ground floor or any floor level. A plinth area rate of building is estimated by identifying the plinth area cost rate of similar constructed buildings in the area.

Essential factors to consider when applying this method include foundation type, building height, type of materials to use, roof construction, and finishes.

3.2) Cubic Method of Estimating

The cubic method of estimating, also known as the cube rate cost estimate, is an effective strategy for determining cost estimates for multi-storey buildings. This type of estimate involves multiplying the volume content of the building by a rate per cubic meter.

This is a more accurate approach than just a plinth estimate, as it encompasses the entire volume of the building, from the floor to the rooftop.

3.3) Square Root Estimate

The square foot estimate approach, widely used in the construction and real estate sectors, provides a straightforward and efficient method for estimating costs based on area. Stakeholders can get a ballpark estimate of project costs by multiplying the total square footage by a predetermined unit cost. Despite being straightforward, this approach provides quick insights for initial budgeting and viability analyses.

3.4) Capacity Cost Factoring Unit

The capacity cost factoring unit approach considers both production capacity and technological specifications. It’s specifically designed for industrial projects with complicated machinery and equipment requirements. Stakeholders can obtain estimates that align with production objectives and operational requirements by accounting for equipment expenses per unit of capacity. This approach provides relevance and specificity for applications requiring specialist equipment.

3.5) Unit Cost Estimate

A mainstay of construction estimates, the unit cost estimate approach divides expenditures into distinct units like square meters or cubic yards. Achieving cost control and budget management is made easier for stakeholders by standardizing unit pricing for labor, materials, and overheads. This approach provides versatility and adaptability for a wide range of project sizes and types.

3.6) Equipment Factored Estimate

The equipment factored estimate approach incorporates equipment expenses directly into the estimated process for projects that largely rely on machinery and equipment. A thorough estimate that considers all project components can be obtained by stakeholders by factoring in equipment rates, materials, and labor expenses. With this approach, budgeting for projects that require a lot of equipment becomes accurate and accountable.

3.7) Assembly and System Estimates

This estimation method provides an integrated approach to cost estimation in projects involving complex assemblies and integrated systems. Stakeholders can obtain estimates that accurately represent the project’s interconnectedness by examining the interactions between its components and subsystems. This approach encourages coherence and synergy in the cost estimation of complex buildings.

4) Modular Estimating

This approach involves grouping project components into modules or units of work and assigning them a predefined cost based on materials, labor, and equipment needs. The modules can be rooms, floors, sections of the infrastructure, or system packages, such as HVAC, electrical, and piping. It is particularly useful for modular construction or projects with numerous standardized elements, such as hospitals, hotels, or residential developments. Modular estimating enhances speed and consistency in the estimating process, allowing for early budgeting even when detailed drawings are not available. It also supports value engineering by making it easy to swap or adjust modules.

5) Bottom-Up Estimating

Bottom-up estimating carefully constructs estimates from the bottom up using an in-depth study and itemized breakdowns as a foundation. Through the consolidation of expenses for distinct elements and undertakings, interested parties can create comprehensive estimates that ensure no detail is overlooked. This approach fosters accountability and transparency, enabling stakeholders to understand the intricacies of project expenses.

6) Top-Down Estimating

This method is the opposite of the bottom-up one discussed above. In this case, the total cost of the project is defined based on opinions from experts or data from similar past projects. The accuracy of the estimate is primarily based on the similarities with past projects or the level of experience of the experts. The method is mainly used in early planning stages when there are not enough project details available. It is handy for initial decision-making, as it takes less time and effort to complete, and estimates are flexible, allowing for adjustments as new information becomes available.

7) Resource-Based Estimating

As its name suggests, resource-based estimates rely on the resource requirements of a project, such as materials, labor, equipment, and others, to calculate total costs. Instead of applying broad assumptions or relying on historical data, this approach estimates costs by calculating resource requirements in detail and assigning a specific unit cost to each one. Unit costs are usually based on market prices, supplier costs, or internal cost databases. This method is particularly useful for projects with a well-defined scope, as it enhances accuracy and transparency. However, it can be time-consuming and complex.

8) Three-Point Estimate

The three-point estimate technique incorporates uncertainty and risk management concepts by considering the most likely, pessimistic, and optimistic scenarios. Stakeholders can create estimates that account for variability and risk by considering best-case, worst-case, and most probable scenarios. This approach ensures robust project planning and execution by promoting preparedness and resilience in the face of unpredictability.

9) Production Rate Estimating

This method is about estimating labor and equipment costs based on performance and productivity. Like many other techniques mentioned on this list, it utilizes historical productivity data from past projects to calculate costs accurately, such as the cubic meters of concrete poured per hour or the square meters of drywall installed per day. It relies on the bottom-up method to identify the quantities of work required for each activity and price them, considering factors like site location, complexity, and others. These values are multiplied by the corresponding unit costs (labor rates, equipment rentals, material costs) to produce a detailed estimate.

10) The Delphi Method

The Delphi technique gathers feedback from a panel of experts to reach a consensus estimate by utilizing expert judgment and collective intelligence. Through a process of iterative opinion collection and synthesis, stakeholders can derive estimates that represent collective wisdom. By encouraging cooperation and the exchange of knowledge, this approach reduces estimating biases and uncertainties.

11) Expert Judgement Estimating

The next entry in our building cost estimation methods involves consulting an expert or a group of experts, such as engineers, architects, or contractors, regarding various aspects of the project, including duration, costs, and risks. This method is typically employed when there is insufficient historical data for initial estimates or when project aspects are unique and require expert feedback. It is important not to confuse this technique with the Delphi method described above. While they both rely on expert feedback, the Delphi method offers a more structured and systematic approach to achieving consensus among experts, making it particularly valuable for complex construction projects with high levels of uncertainty. In contrast, Expert Judgment Estimating offers quick, experience-based insights, making it suitable for early-stage estimations or when time constraints are present.

12) Model-Based Estimating

Model-based estimates rely on powerful 3D models and BIM software to calculate the costs of a project. The model contains real-time data about the project, mixing time and money on a single, digital interface. This helps to eliminate the need for manual calculations, ensuring high levels of accuracy and speed. The method is mainly used in complex projects where accuracy and agility are crucial. However, its success depends heavily on the quality of the model and the consistency of the data input. It also requires skilled personnel and compatible BIM management software. Many countries are mandating the use of BIM in construction projects across both the public and private sectors to manage workflows effectively.

13) Vendor Bid Analysis

As its name suggests, this method is used during the construction bidding process to assess competing bids and determine cost estimates when purchasing goods and services from outside suppliers. Through a thorough examination of offers from several vendors, stakeholders may determine which solutions are the most economical and competitive. By ensuring fairness and transparency in the vendor selection process, this strategy maximizes project value.

14) Probabilistic Estimating

This approach acknowledges that a level of uncertainty is inherent in construction projects. Therefore, it assigns ranges of possible costs to each project component, rather than a fixed value. The Monte Carlo simulation technique is used to run thousands of iterations of possible scenarios, producing a cost distribution curve that identifies likely outcomes, from best-case to worst-case. This approach is beneficial for complex projects with high levels of uncertainty or those in volatile market environments.

The method is often used interchangeably with the three-point estimating approach discussed earlier. However, they are not the same. Three-point estimating is a simpler and more straightforward version of the probabilistic method, which utilizes advanced statistical techniques to provide more robust risk-informed decisions.

15) Whole-Life Cost Estimating

This method extends beyond estimating the costs of a project; it calculates the total costs of the entire lifespan of the structure, encompassing initial construction, operation, maintenance, and eventual disposal. It includes upfront capital costs, ongoing operational expenses (such as repairs, servicing, and utilities), and end-of-life decommissioning. It is ideal for projects and clients that prioritize long-term value over short-term returns. During the design phase, this method supports procurement decisions by comparing alternatives based on their long-term economic impact. For example, selecting higher-quality materials with historically low repair rates can help reduce maintenance costs. Due to the complexity of the method, companies typically rely on BIM and asset management data to achieve accurate results.

16) Reserve Analysis

The reserve analysis technique is used for construction risk management to determine the amount of contingency or reserve budget that needs to be allocated to account for design changes, delays, scope creep, or other unexpected conditions. It is performed by identifying potential risks, their probability, and potential costs, and then calculating how much budget should be set aside to address them. Companies often rely on additional types of cost estimates in project management, such as expert judgment or historical data analysis, to effectively analyze costs and expenses. While this method does not predict total project costs, it enhances the reliability of estimates by accounting for risk, making it a vital component of any comprehensive cost estimation strategy.

What Costs Are Included in Construction Estimation?

A construction cost estimation encompasses a comprehensive array of expenses, meticulously calculated to provide a holistic view of project finances. Included within this estimation are direct costs such as materials, labor, and equipment, which form the backbone of project execution. Additionally, indirect costs such as permits, fees, and overheads are factored into account for administrative and regulatory requirements. Contingency allowances for unforeseen circumstances and inflationary adjustments ensure financial resilience and accuracy in budgeting.

Together, these components form a detailed and transparent assessment of the financial resources required to bring a construction project to fruition. Implementing a modern construction reporting system to track all expenses in real-time is a great practice to get a 360-view of the project and make informed cost-related decisions.

Where Do Construction Cost Estimators Find Their Data?

A well-crafted budget is the foundation of any successful construction project. Construction cost estimators are at the center of this budgeting process; they have the difficult job of producing precise estimates in the face of a plethora of unknowns. Let’s explore some of the knowledge bases that construction cost estimators use to traverse the tricky landscape of project costing.

1) Historical Data

History is a trustworthy source of information, and the building industry is no different. Estimators extract priceless information on labor, materials, costs, and schedules by analyzing historical data from completed projects. Through a review of previous, comparable project outcomes, estimators can identify patterns, trends, and baselines that inform their current projections. By serving as a storehouse of knowledge gained from the past, historical data enables estimators to improve the precision of their forecasts.

2) Cost Research

It’s critical to stay up to date on construction trends and industry dynamics in the ever-changing construction sector. To obtain the most recent data on material prices, labor rates, equipment costs, and regulatory requirements, construction cost estimators conduct extensive cost research. To monitor price changes and identify cost-saving options, estimators review supplier catalogs, market assessments, and industry publications. They can reduce cost overruns and represent real-time realities by staying updated on market dynamics and adjusting their forecasts accordingly.

3) Expert Knowledge

The foundation of a successful building cost estimation is expertise. Experts in their field contribute a wealth of experience, intuition, and domain knowledge to the estimation process, enhancing it with priceless judgment and insights. To gain a thorough understanding of project requirements and limitations, construction cost estimators consult with architects, engineers, contractors, and other industry stakeholders to ensure accurate and comprehensive estimates. Through group brainstorming sessions, expert consultations, and peer evaluations, estimators utilize collective intelligence to refine their estimates and anticipate potential obstacles.

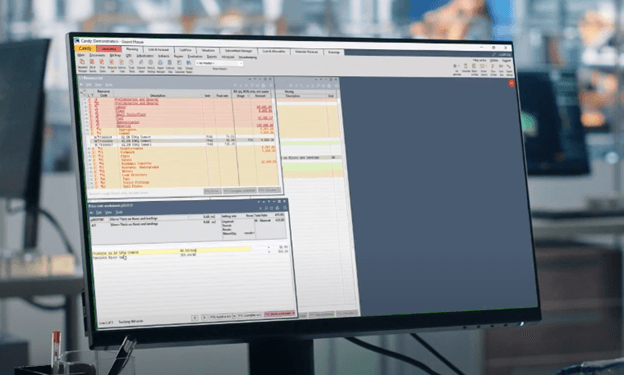

Using Estimating Software for Accurate Results

As a contractor, regardless of the type of construction cost estimation methods you are using, you want them to be as accurate and efficient as possible. Poorly done estimates can result in wasted resources, wasted time, and the risk of running over budget. When creating an estimate, it is essential to remove any risk of error.

This is where using estimator software can make a world of difference. Modern solutions, such as RIB Candy, enable estimators to produce faster and more accurate results, allowing them to win more bids and manage projects more efficiently.

Candy’s intuitive quantity takeoff, estimating, and planning modules work together by linking time and money on a single platform. Users can perform intuitive on-screen takeoffs and electronically compile a robust Bill of Quantities to support bidding. Project items can be priced using first principle resource-based estimating, supported by powerful pricing libraries for accurate and agile estimates. Items from the bill of quantities can be allocated to the schedule, allowing for cost-conscious planning. Candy’s Master Libraries will enable you to reuse and repurpose your historical data to support reliable and competitive estimates.

Additional features for subcontractor management, forecasting, cash flow analysis, valuations, reporting, and more enable efficient project management throughout the entire project lifecycle. The centralized nature of the platform fosters a collaborative environment that reduces errors and increases productivity.

Final Thoughts

Cost estimations are a critical part of any project. They help contractors understand the project’s requirements and clients understand their budget and financial needs. Different types of estimations are used at various stages of the project to ensure efficient progress.

Professional construction estimation software, such as RIB Candy, provides powerful tender and resource analysis, planning, forecasting, and ‘cost vs. allowable’ reports. Its powerful features are also combined into a single-user interface to eliminate departmental silos and boost communication.

Furthermore, it provides pricing capabilities using First Principles Resource-Based Estimating to substantially improve the speed, accuracy, transparency, and auditability of your estimates. If you are ready to enjoy greater accuracy, faster cost estimation, and overall project control, get your free demo for RIB Candy today!

Get My Free RIB Candy Demo Now

Most Recent

11 mins read

10 mins read

10 mins read

29 mins read

Blog Categories

Ebook