11 mins read

A Guide On How To Do A Construction Takeoff Accurately

- What Is a Takeoff in Construction?

- Construction Takeoffs Use Cases

- Who Is Responsible for Doing a Takeoff in Construction?

- Difference Between Construction Takeoff and Estimating

- How to Do a Takeoff in Construction: Tips & Best Practices

- What Are the Benefits of Using Construction Takeoff Software?

- The Role of Construction Takeoffs for Sustainability

- Final Thoughts

The competitive nature of today’s construction industry makes thoughtful planning more important than ever. Any mistakes that happen during preconstruction planning can affect the entire project later on, making it more expensive and less time efficient.

One of the tasks required at the initial planning stage is to define and quantify the components required to complete the project. This measurement process, known as a takeoff, gives construction estimators and other stakeholders the knowledge they need to generate accurate cost estimates.

Construction takeoffs help projects stick to the budget by estimating the exact quantities of materials they need. Knowing how to do it properly will, therefore, enable better management of the overall workflow of the project.

If you are new to the topic or are just looking for a quick refresher, this guide will explore exactly how to do a construction takeoff and how you can use software for more accurate and sustainable results.

Let’s dive in!

What Is a Takeoff in Construction?

A construction takeoff is the process of measuring and listing the components required to complete a project. Takeoffs are a fundamental part of the construction cost estimation process as they provide the initial information needed to calculate project costs.

Also known as quantity takeoff, the “takeoff” part of the name refers to estimators taking off items from the plans or blueprints and figuring out exactly how much of each they will need to complete the project. How many bricks, how much concrete, how many meters of wood, etc. This is done to create a total list of all the components needed so they can estimate how much it will all cost.

In theory, a takeoff in construction is about listing materials required to complete the project. In practice, it is a complex task that requires plenty of skill and precision. For large-scale and complex projects, accurately estimating the construction takeoff is no easy feat. If any quantities are estimated incorrectly, it can result in a delayed timeline as well as unwanted changes to the budget.

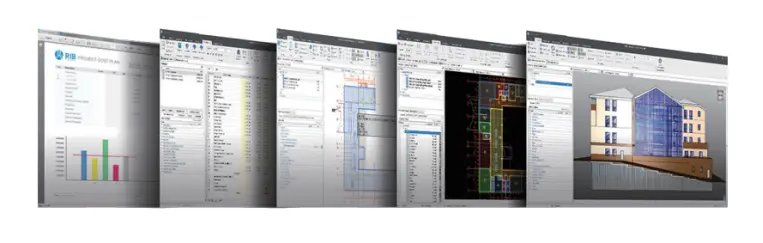

To conduct the most accurate analysis, it’s best to use specialized construction estimating software like RIB Candy. This will vastly improve the outcome of the takeoff, resulting in a much smoother and more efficient project going forward.

Construction Takeoffs Use Cases

Takeoffs are valuable for different use cases in a construction project, including:

- Estimating: The most valuable use case for takeoffs is to estimate costs. Takeoffs are a crucial step in the estimation process. Once completed, the estimator can price the materials and add labor hours, equipment, taxes, and other costs to get a complete breakdown of project expenses.

- Bidding: Takeoffs are also necessary for the construction bidding process. Contractors must do an accurate estimation of resources to price their bids; otherwise, they can end up charging less and losing money later on or charging more and losing the bid. Therefore, doing an accurate takeoff can determine whether they win a project bid and maximize profitability.

- Procuring materials: Efficient construction procurement management requires a detailed breakdown of the materials to be purchased. Having all materials listed in a well-structured document can prevent procurement managers from purchasing more or less of what is needed and avoid any budget overruns, time delays, or other issues.

Who Is Responsible for Doing a Takeoff in Construction?

Now that you know what a takeoff in construction is and what it is used for, let’s explore who is responsible for doing it.

In most cases, project takeoffs are one of the key estimator or quantity surveyor responsibilities. These professionals often have years of experience in the field and can leverage software to do the most accurate takeoffs. Depending on the project’s size, there might be more than one estimator working simultaneously. Mega-building projects require specialized estimators to work on specific areas or scopes of work.

Contractors and subcontractors can also be responsible for doing a takeoff on smaller projects or for their own bidding purposes.

Difference Between Construction Takeoff and Estimating

While the two processes are highly connected, it is important to understand the differences. Construction takeoffs primarily involve quantifying components, while construction estimates involve adding prices to those components, as well as calculating other related project costs.

Cost estimation forms the basis for any project. Before a project can begin, the client needs to know how much it will cost to plan the budget effectively. Professional estimators rely on takeoffs to accurately estimate how much it will cost to complete the project.

Accuracy is critical here. Without accurate construction takeoffs and estimations, all kinds of issues can arise. The project can easily run over budget and over time. Or you can end up with too many materials and have excess waste.

Thus, accurate estimates are vital for the proper planning of a construction project. It enables contractors to submit better bids, thereby gaining a competitive edge over other contractors. In addition, it helps them maintain a good bottom line for each project.

How to Do a Takeoff in Construction: Tips & Best Practices

By now, you should have a basic understanding of what project takeoffs are and their importance. But how do you actually do it accurately? Below, we discuss some key tips and best practices to succeed in the process!

1) Determine your needs

The first step in the process is to gather and carefully review all project documents to ensure you understand the scope and needs. If you don’t understand what the project is all about, you might encounter issues that will require more work later on. At this stage, you might realize that the project has some specific requirements that need to be considered when selecting materials; therefore, paying close attention to details is paramount.

2) Define a method

Once you have determined your needs and goals, you should pick a takeoff method to start the process. There are two main methods: manual and digital.

The manual takeoff method is the most traditional way of doing it, and it involves printing the blueprints and documents and using a scale ruler to get the information you need. This process is quite time-consuming and highly subject to manual error. However, it is considered less expensive than investing in technology, which is why it can be the preferred method for really small projects. It is also used as a way to double-check what was done using the digital method.

On the other side, digital takeoff methods are completed with the help of the latest technology available, making the process significantly faster, more accurate, and more efficient. 2D takeoff can still be undertaken digitally from drawings, however, one of the most effective ways to do a digital takeoff is by using professional 3D takeoff software. This innovative solution offers a digital 3D model of the entire design, allowing you to automatically extract quantities and costs.

3) Work with a checklist

A takeoff can be an extensive process, with a massive list of components required. This can result in mistakes and missed items if there is no clear checklist to follow. Make sure to have a kind of roadmap created that the estimator can work from. A checklist can also serve as a template for future projects, saving you time and money.

4) Use updated plans

Construction blueprints tend to go through many revisions and changes, and accurate takeoffs can only be achieved if everyone involved in the project works off the same version. Using an old set of plans will result in total revision, as well as wasted time and resources. Using cloud-based construction software can make your life a lot easier, as all plans and project documents are stored online and always updated for everyone who needs to access them.

5) List the components

Up to this point, you understand the project, have picked a takeoff method, have your checklist ready, and have your plans up to date, so you are ready to start listing and quantifying the components. For example, the number of doors and windows, the area of walls and flooring, the volume of foundations, etc.

If you are doing your takeoffs digitally, then your software will quantify components automatically. You’ll just need to double-check that everything is correct. If you are doing it manually, then you’ll need to quantify everything on your own, being very careful not to make any mistakes.

Remember takeoffs are quite detailed, so everything needs to be listed in as much detail as possible. For example, you want to avoid taking off just for “flooring.” Instead, list all types of flooring materials that will be used, such as carpets, tiles, or lumber.

6) Take measurements

Now it is time to take measurements. Here, you look at the blueprints, verify the scale, and measure the different elements. These measurements are later used to quantify the materials. For example, you need to measure the surface area of the walls to figure out how much paint or drywall you’ll require.

When learning how to do a construction takeoff, accuracy and precision are the key features. However, estimators should add a specific percentage of the measurements to account for any waste. This will help to create a more consistent and accurate cost scale.

7) Determine quantities

With your list of components and measurements ready, you are set to start calculating quantities. Quantities are usually measured in four ways: unit counts, length, area, and volume. The measurement type depends on how the component is sold. For example, it is better to measure electrical cables in length rather than units; likewise, it is best to measure flooring by the area but foundations by their volume.

8) Calculate costs

With your quantities determined, you have all the information you need to start estimating the costs of the components. Here, you should calculate the unit costs as well as the total cost for each section of the takeoff. To figure out the potential costs, estimators can either rely on their experience or, in some cases, use quotes already provided by suppliers. Some takeoff tools also include updated pricing databases that can help make the process faster and easier.

9) Use the right software

No matter how experienced or skilled your estimator may be, there is always the risk of human error. Even the smallest mistake made somewhere in a construction takeoff can result in a major difference later on down the line. For more accurate and efficient takeoffs, using fit-for-purpose software is the first step. Professional construction estimating software has been designed to avoid human error and automate different processes. Not only will this allow you to achieve estimates and bids faster and easier, but it will also result in far greater accuracy.

10) Communicate with stakeholders

While this might not always be obvious, construction takeoffs do require communication and close collaboration with other stakeholders to maintain their accuracy. The expertise and knowledge of designers, construction architects, subcontractors, and material manufacturers combine to provide a more detailed description of the project, and allow any questions to be answered quickly. For example, manufacturers can provide detailed information on standard quantities, unit of measure, and availability, while contractors and architects can explain the construction methods that must be followed and how they impact the takeoff process.

Communicating with stakeholders throughout the takeoff and estimation processes also ensures any changes are addressed immediately, so that corrections or adjustments can be made. This constant communication minimizes the risk of errors or omissions that can impact the accuracy of the takeoff and derail the project budget or schedule.

11) Consider material buffers and rework

A takeoff in construction can be a balancing act between too much material and too little, with the goal of avoiding both waste and shortages. Logically, it would follow that an accurate takeoff would precisely match the drawing requirements for each material. While this may be true in some cases, new construction methods, fragile materials like tile, glass, and limestone, and inevitable errors call for buffer quantities to be added. Reviewing past projects and consulting with experts are two of the best ways to determine appropriate buffers.

All projects try to minimize rework, but much like the occasional human error or workmanship issue, these situations are unavoidable. While continually adjusting the takeoff quantity to adapt to the changes, quantity surveyors should also provide input to procurement teams to create appropriate rework buffers.

12) Double-check results

Doing it right first time is a meaningful objective in every situation, including construction takeoffs and estimating, but double-checking your work is still advisable. This is especially true when manual takeoff methods are used to transpose quantities from drawings to Excel spreadsheets. Even when digital takeoff methods are used, it is still advisable to recheck inputs like drawing scale and material specifications and evaluate the results to ensure they align with project expectations and the proposed budget.

Mistakes and errors in takeoffs can lead to incorrect estimates and material planning issues with potentially serious consequences. While incorrect quantities can cause material waste or shortages, takeoffs completed using incorrect material types can have an even more serious impact on building design and safety.

13) Continuously learn and improve

As you learn how to do a takeoff in construction, you will find that no two projects are alike. Rather than viewing this as a problem, it is important to consider the continuous improvement and learning opportunities presented by the takeoff process. Different materials require different handling and counting methods, while the construction processes utilized for each building present challenges that must be considered from the earliest planning stages, and be factored into the construction takeoff.

Software tools simplify the analysis and research that go into a successful takeoff, which can free up time for quantity surveyors, estimators, and contractors to focus on the unique or unusual aspects of each project and develop tools and strategies to ensure these differences do not impact takeoff accuracy.

What Are the Benefits of Using Construction Takeoff Software?

Up to this point, we have already mentioned many of the benefits of doing accurate takeoffs on construction projects. We will now consider the value of professional construction takeoff software, and the many ways it can improve takeoffs in construction. The software you decide to invest in can significantly enhance your takeoff process by offering advanced features that eliminate manual tasks and the risk of human error.

An accurate construction takeoff, supported by professional software, helps you to understand the components needed from the early stages of the project. This allows for better planning and prevents any issues later on, saving the project time and money by not having to fix issues caused by poor calculations during planning.

Here are a few ways that this technology enhances the process:

Automation and accuracy

If estimators work manually, they have to determine the exact quantities of a project based on the blueprints or design documents. Not only is this incredibly time-consuming, but it also leaves a lot of room for error. No matter how experienced an estimator is, there is always the risk of a simple human error. And when it comes to construction takeoffs, even the smallest mistake can have a dramatic effect.

By using construction takeoff software, estimators can automate this process. The software can generate a list of materials and quantities based on the latest digital blueprints, saving vast amounts of time, and ensuring complete accuracy.

Construction takeoff tools can also eliminate errors by using measurements that are extracted directly from the computer-aided design (CAD) quantity properties. The measurements can be superimposed onto various CAD revisions, highlighting under- and over-measurements.

A simplified process

Manual takeoffs are complex. There are various formulas and methods to do it, and estimators need to carefully recheck all their work to ensure it is free from errors. Thus, they need to be highly skilled and experienced.

Construction takeoff software completely simplifies this process with automated quantity calculations, appropriate measurement types, and built-in formulas to use. As a result, you can create accurate estimations faster and with more ease.

Advanced takeoff technologies

Combining takeoffs with other functions helps to enhance and streamline various project processes. Here are two key technologies that should be integrated with your takeoff solution to enhance efficiency and reliability.

Data Integration

Takeoff technology combines estimating, planning, and on-site control into one central platform. It links the bill of quantities with your construction schedule for better project management. This saves you from having to re-enter this type of data on different platforms or systems. As a result, it saves time and vastly improves accuracy.

Reporting

Construction reporting tools are necessary during a project to help contractors make informed decisions. These tools use data from the takeoffs to create accurate and insightful reports. Construction managers can use these reports to make smart, data-backed decisions.

Greater flexibility

Enhanced flexibility is one of the greatest benefits of construction takeoff software, since revisions and changes can be factored into the takeoffs much more quickly. This makes it possible to review output for multiple design scenarios simultaneously and compare the takeoffs to better understand the cost impact of each option. Cloud-based software tools also make it easier for stakeholders in different locations to participate in the takeoff process.

RIB CostX takeoff and estimation software provides unprecedented flexibility, with revision tracking features that automatically compare plans and highlight changes. Live links to the estimate also make it easier to understand the cost impact in real time. Support for a wide variety of drawing formats, including 2D drawings, 3D models, and PDF files, provides the ultimate in takeoff flexibility for users.

Carbon calculations

Embodied carbon calculations are a key element of sustainable building practices, since they allow the carbon content and emissions associated with each individual item to be predicted for its entire lifecycle. This includes all manufacturing, transportation, and demolition processes, as well as the specific properties of the material itself. A takeoff that includes carbon calculations helps to determine the sustainability profile and environmental impact of the entire structure.

Cost estimating and embodied carbon accounting are fully integrated in the RIB CostX platform, which allows design teams to weigh sustainability vs cost on a level playing field and assess the impact of each individual element. CostX also supports advanced 6D Building Information Modeling (BIM) practices, with carbon footprint, energy consumption, and other sustainability metrics seamlessly integrated into the digital model.

BIM support

While BIM adoption has not yet expanded to every region and company, many of the biggest and most ambitious construction projects in the world now credit BIM for their design and construction efficiency and success. With all project design and material information conveniently maintained in a collaborative digital platform, BIM is redefining construction takeoff tools by pulling information directly from detailed digital models to save time and reduce errors.

RIB CostX includes 3D BIM capabilities to quickly and accurately estimate costs and quantities based on the large data repositories of project BIM files. This key feature provides a gateway to the future of construction takeoffs by improving design quality, eliminating mistakes, and creating a solid foundation for construction businesses as the industry moves towards automated solutions and more sustainable buildings and structures.

The Role of Construction Takeoffs for Sustainability

Sustainability in the construction industry is much more than a passing trend, with 57% of residents willing to pay a premium for a more environmentally-friendly home, and builders around the world striving for ‘green’ certifications that demonstrate their commitment to sustainable construction practices.

Software tools are the key to making buildings, construction processes, and materials as efficient and environmentally friendly as possible. While BIM and digital twins allow designers to model and optimize their sustainable designs, the construction takeoff process helps to optimize resource use and minimize waste.

The demand for sustainable buildings continues to grow, but the additional cost associated with green construction can sometimes discourage clients from selecting carbon neutral materials, or pursuing design options like rainwater harvesting systems, living roofs, and built-in solar panels. An effective construction takeoff helps to offset this cost impact by minimizing material waste and utilizing resources more effectively, just as these advanced features minimize operating costs over the lifespan of the project.

Construction takeoff tools and software magnify the positive impact on sustainability with additional benefits that include:

Sustainable material selection

Accurate takeoffs pulling information straight from 2D or 3D design files make it easier to evaluate the cost impact and carbon footprint of various material choices quickly. For example, sustainable construction materials like bamboo, mycelium (mushroom), and cork can be compared to their more traditional material counterparts like timber, brick, and sheet rock using side-by-side embodied carbon comparisons.

Flexible construction options

Environmentally friendly building methods involving precast concrete and other prefabricated building elements provide a sustainable alternative by reducing material and energy waste both on and off the jobsite. These practices can only be successful when the exact quantities of materials are known. Construction takeoffs provide this essential information.

Support for LEED certification

Construction takeoff and estimation software establishes a central repository to track metrics like recyclable content, waste diversion, and material percentages that are needed to obtain coveted LEED and BREEAM certifications. These standards grade the sustainability of commercial, office, and residential buildings using preset criteria. Takeoff software tools also make it easier to generate reports in support of the green certification application process.

Waste reduction is perhaps the greatest environmental contribution of takeoffs in construction, with lean building methods setting a tone that can last throughout the lifespan of the building. Excess materials that were once commonplace often found their way to landfills and dumps, or were returned to suppliers using inefficient transportation and storage methods. Accurate takeoffs ensure only materials that are truly needed will be ordered and consumed.

Sustainable building practices are quickly becoming the norm, as clients and occupants recognize the benefits of clean energy, reduced resource depletion, and enhanced indoor environmental quality. Government incentives and reduced operational costs have only increased this demand. Construction takeoff software will continue to be a key element of this ongoing transformation in the industry.

Final Thoughts

Knowing how to do a takeoff accurately can really make or break a project. The early preconstruction planning phases are often the most critical for a successful project. As such, plenty of focus needs to be placed on these processes.

An accurate takeoff will result in stronger cost estimation, improved bids, and smoother construction operation. Any contractor should be sure to utilize the best construction software solutions and practices available to achieve accuracy, efficiency, and sustainability when doing takeoffs.

Our state-of-the-art BIM takeoff software, RIB CostX, is an all-in-one solution for professional takeoff, estimating, and reporting. Its flexibility in deployment and capabilities enable its users to perform 2D takeoffs from supported drawing types like PDFs or CAD files and 3D BIM takeoffs directly from BIM files.

If you are ready to increase efficiency and collaboration to achieve accurate takeoffs, get a demo for RIB CostX today!

Most Recent

11 mins read

10 mins read

10 mins read

29 mins read

Blog Categories

Ebook