10 mins read

Understanding Cost Estimation In Construction Projects

- What Is Cost Estimation in Construction?

- Importance of Cost Estimation in Construction Projects

- The Construction Estimation Process Explained

- Levels of Cost Estimation in Construction Projects

- How To Estimate Construction Costs

- Common Construction Cost Estimation Challenges

- What Can Construction Estimating Software Do for You?

- Final Thoughts

Good cost estimation in construction is a vital aspect of any new project. Accurately estimating costs will help prevent potential budget issues and financial losses. This is why it’s important to have a precise breakdown of all expenses right from preconstruction planning onwards.

In this blog post, we explain the basics of construction estimating, including a step-by-step description of the process and a list of common challenges. We also review some of the important benefits of software solutions for timely and accurate estimates.

What Is Cost Estimation in Construction?

Cost estimating in construction is the process of calculating the overall required costs for a new building project, including direct and indirect costs. Contractors use them when they decide if they are going to bid on a project or not.

Clients considering large projects often request numerous cost estimates, including those prepared by contractors and those calculated by independent estimators. Being able to accurately forecast costs will help you stand out from the rest.

Accurate construction cost estimation also helps define the project’s scope, the resources needed, the time frame, and the budget.

For example, accurate estimates will enable the builders to make sure they order the right number of materials and stay in line with the budget.

When Should You Do a Construction Cost Estimation?

The sooner you start to estimate construction costs, the better, preferably when the project is still in the concept phase. Without a clear idea of the project expenses, it will become difficult to provide an accurate cost estimate or make a winning bid.

You may also run into potential challenges, such as taking on more than you can handle or suffering losses instead of making a profit. That is why you must produce a detailed cost estimate long before you start construction.

Keep in mind that there is a difference between cost estimation for bids and cost estimation for project management:

When creating a cost estimation for the construction bidding process, data from the project’s documents are used to make a more detailed cost estimate. This includes design estimates, construction processes, and all the direct and indirect costs involved. Sometimes, this can be the last stage of a project, since your bid may be declined, but you still have the expenses you made with creating the bid.

Estimates for construction cost control are done after the contract has been signed, but before construction commences. This facilitates proactive planning and forecasting potential complications. In this way, all parties ensure adherence to the project timeline and budget.

Who Is Responsible for Construction Cost Estimating?

Depending on the type and size of a project, either an individual or a team may be responsible for construction cost estimation. Typically, a large company will have a dedicated construction estimator, who is tasked with preparing and estimating construction costs.

Project managers may also use project estimation and planning software to help them develop accurate programs, budgets, and cash flow forecasts.

In addition, estimators and project managers require the input of construction architects and engineers to ensure that a project is financially feasible and meets the scope requirements.

Estimators reviewing blueprints, specifications, historical data, and other information often collaborate with these specialists throughout the process to ensure their assumptions are correct and the information sources they rely on are up to date.

In some cases, outside experts like sustainable construction consultants or specialty contractors also get involved in estimating construction costs, especially when new building practices or materials are involved.

How To Calculate Construction Costs?

When calculating construction costs, there are various types of costs you need to consider. Make calculations based on the following:

- Direct costs, such as materials, labor, and equipment expenses

- Indirect costs, which include overhead, site establishment costs, project team, supervision, utilities, legal fees, permits, and more

- Subcontractor costs, which include specialized contracted work expenses such as labor and materials

- Markup and risk provisions, which are added to actual material and labor costs by the contractor to account for overhead, profits, and unforeseen cost increases or delays.

Various calculation methods and strategies have evolved over the years to make it easier to create a reliable total based on the sum of disparate costs. For example, unit cost methods rely on accurate takeoffs and labor time estimates to compile the total based on all individual elements. Square footage methods assess the total cost by multiplying the cost of labor and materials for a pre-defined space, based on the total size of the area to be completed.

Importance of Cost Estimation in Construction Projects

With precise estimates, project managers can identify potential risks, create realistic timelines, and develop contingency plans to ensure efficient project management in construction. This level of planning helps to ensure that construction projects are completed on time and within budget.

On the other hand, without an accurate construction cost estimate, owners cannot determine whether a project is feasible within the allotted budget.

Of course, estimating the cost of any project with absolute precision is impossible, and unforeseen reasons can always cause a project to fail. A skilled estimator will, however, account for as many factors as necessary to create the best possible estimate. Some of the considerations that go into successful construction cost estimating include:

Financial planning

An estimate of construction costs is much more than an isolated activity, since it sets the stage for important financial decisions and activities that follow. This includes the formation of budgets and client expectations that define financial success or failure throughout the project. When outside funding is secured, an accurate estimate builds investor confidence in the viability of the project and the credibility of the team.

Accurate estimates also prevent cost overruns and budget shortfalls that can derail progress or lead to cost-cutting measures late in the project schedule. All future decisions regarding scope, scheduling, and procurement require an accurate estimate as an input to ensure positive financial outcomes.

Risk management

Construction risk management practices involve an evaluation of all design, site, material, logistical, and financial risks to weigh their importance and develop appropriate mitigation strategies and corrective actions. A clear picture of anticipated costs is needed to get the most out of the risk management process, since this information allows the cross-functional team to understand the impact of price hikes, natural disasters, labor disputes, and other situations leading to variation or overruns.

Contingency planning is where the cost estimation and risk management processes overlap, since assessing the likelihood of unforeseen events affecting costs allows the project team to recommend realistic contingency budgets that prevent cost overruns without inflating the schedule unnecessarily.

Competitive bidding

Accurate estimates allow contractors to submit bids that account for all relevant project costs while still providing a reasonable profit margin. Competitive bids among multiple contractors or subcontractors generally indicate that estimators have taken important cost factors into account, and the contractors submitting bids have recognized and factored in the same cost drivers.

Estimates that are grounded in reality make it easier to recognize underbidding practices that can lead to cut corners, incomplete work, or poor quality, as well as overbidding attempts that rely on a lack of client knowledge to artificially inflate bid amounts.

Resource allocation

Resource allocation is the process of strategically distributing and scheduling resources, including financial resources, throughout the life of a project. Careful planning, monitoring, and adjusting are needed to ensure this process is performed effectively. Planners must determine when each resource is available, then build a schedule that utilizes resources in the right sequence to keep the project on track and avoid any delays.

Accurately breaking down costs for labor, material, and equipment through construction estimating helps to ensure these resources also fit within the project budget and will be available when needed.

Profitability

Learning how to estimate construction costs accurately is also a good way to ensure project profitability. An accurate assessment of expected costs enables contractors to determine the minimum price they need to cover all costs while earning a profit, or set their bid based on profit expectations. If the estimate is later found to be inaccurate, this can eat into contractor profits, especially when they are working under a fixed price (lump-sum) contract that does not allow for cost adjustments.

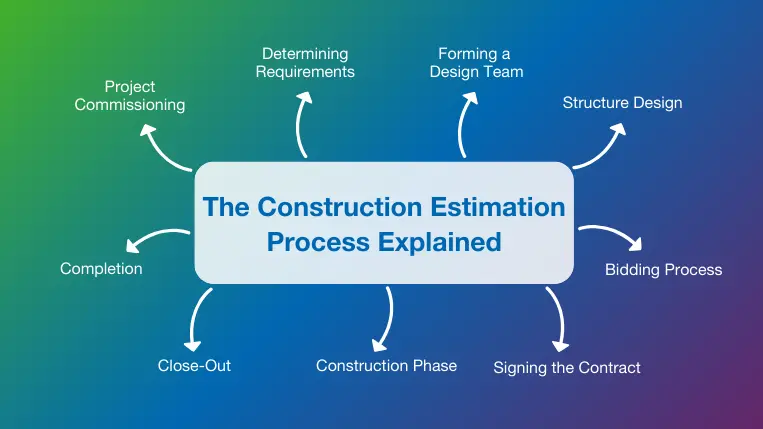

The Construction Estimation Process Explained

To know how to do a cost estimate, you must understand the construction process. Here are the basic phases of a construction project:

1. Project Commissioning

In essence, commissioning is a verification process that guarantees the builder’s adherence to designing, constructing, and delivering projects in line with the owner’s specifications. Its initiation occurs early during construction and may last until up to one year of occupancy or use. The execution of this process relies on commissioning providers, which is usually an experienced building firm specialized in serving certain functions through proper management methods.

2. Determining Requirements

The initial and most significant stage of any project is pre-design or planning. This requires identifying a project’s requisites such as its function(s), projected expenditure, geographical location, and any legal requirements it must comply with.

3. Forming a Design Team

To form a design team, the project owner hires an architect who will procure other expert consultants. The number of specialized consultants on board depends on the complexity and unique design requirements of the project – for example, those involving acoustics or hazardous materials may require more experts to ensure the design meets the requirements. While architects typically oversee and coordinate designing procedures, engineers also participate in some projects, such as infrastructure and civil industrial projects.

4. Structure Design

In the design process, architects first collaborate with owners to establish overall direction before working more closely with other members of the team. This progression involves moving from a schematic phase, where high-level designs are approved by owners, to a development phase focusing on construction specifics in collaboration with consultants. The last step is producing detailed drawings and specifications for contractors to follow during construction.

5. Bidding Process

Upon finalization, the construction documents are made available for contractors who want to bid on the project. These bidding papers include guidance on how to submit proposals, a draft of the contract agreement, and financial and technical prerequisites required by contractors. These documents define what work will be done and provide grounds for estimating expenses during preparation. To ensure transparent and fair construction bid management, all contractors receive the same information.

6. Signing the Contract

After the bid tendering and selection process, the chosen contractor will proceed to execute a set of contract documents with the owner. These entail bidding papers that will function as an official agreement between both parties. The type of contract can follow various models, such as lump-sum or turnkey contracts (where contractors estimate a fixed amount for the total project cost and finalize it once design plans are almost done).

7. Construction Phase

During this phase, the contractor is responsible for supervising construction work in accordance with the documents provided. To handle specialized aspects of this process such as plumbing or foundation work, general contractors often employ subcontractors for various scopes of tasks. During each stage of development, cost control measures are taken by the contractor to gauge actual expenses against projected costs and ensure profitability.

8. Close-Out

As the builder approaches the final stages of constructing a building, the contractor will request the architect to verify the near-complete status of the project. During this stage, the contractor provides the architect with a document known as the punch/snag list, which contains details of any incomplete work or corrections that must be done. If necessary, other incomplete items will be added to the punch list after the architect has inspected the structure.

9. Completion

Upon completion of all unfinished tasks listed in the punch list, the architect conducts a final inspection to ensure that the contractor has followed construction plans and specifications accordingly. If the structure has been completed according to all specifications, the architect will issue an official certificate of final completion, confirming that the contractor may be paid in full.

Levels of Cost Estimation in Construction Projects

There are different types of construction estimates that can occur throughout the construction process. These levels of estimates can differ depending on which stage of the project you are in.

- The order of magnitude: Determines feasibility before the project starts. This is the first phase and is based around expert judgement and comparative jobs.

- Intermediate estimate: Determining feasibility from using the concept of the general project. This is often used to determine whether a project is worth following through with.

- Preliminary estimate: A slightly more realistic estimate with a more detailed scope. This is the estimate that many projects base their budgets on.

- Substantive estimate: This estimate looks at the project designs, goals, and deliverables. The contractor then creates an estimate based on estimated unit costs.

- Detailed estimate: This is the final stage of estimates and is created when the contractor knows most (or all) of the actual costs of the project. This is the most accurate form of estimate and is used to create tenders and bids.

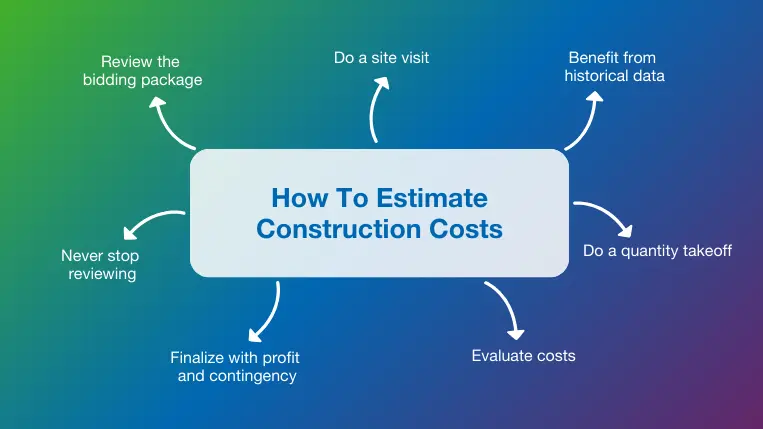

How To Estimate Construction Costs

1. Review the bidding package

The bid documents contain construction specifications and contract documents, which serve as the starting point for understanding the scope of the project and requirements. Project managers should ensure that they have a thorough understanding of these documents.

2. Do a site visit

Conducting a site visit is important as it offers key observations about the environmental and logistical aspects of the project, which can have a considerable impact on its viability and expenses.

3. Benefit from historical data

Historical data is something that a contractor relies on while estimating construction costs. This data can come from a variety of sources, including databases, catalogs of vendor data, and successful past bids (assuming these proved accurate). Regardless of the data source, it’s important to make sure the data is reliable. That is why experienced estimators often recommend using a trusted industry standard source.

4. Do a quantity takeoff

When doing a quantity takeoff, estimators ensure precise calculation of every material necessary for the project, including doors, drywall, concrete, and wiring. During this process, they refer to the provided construction documents as a guide. Advanced takeoff and estimation software allows estimators and quantity surveyors to perform accurate quantity takeoffs quickly based on 2D drawings, 3D CAD files, or building information modeling (BIM) project files.

5. Evaluate costs

Once a complete quantity take-off has been done, contractors will engage with suppliers and vendors to get pricing information, considering several factors:

Labor costs

When estimating labor costs, factors such as worker productivity, the level of expertise needed, and local wage rates must be considered. To guarantee a thorough estimation, bonuses, allowances, and overtime pay should also be considered.

Material costs

Materials are the physical components required for building, such as wood, steel, concrete, and different fixtures. Determining the quantity needed for the project and obtaining supplier pricing are the first steps in estimating material costs. To prevent underestimating costs, fluctuations in material prices, quality variances, and delivery expenses should also be considered.

Equipment costs

When estimating equipment costs, you must consider expenditures for fuel, leasing, maintenance, and operator compensation. Accurate cost forecasting is facilitated by assessing rental agreements, depreciation rates, and equipment lifespans. A thorough cost estimate must also consider probable downtime, repairs, and upgrades.

Insurance costs

Insurance is an essential component of building projects. When assessing insurance costs, variables such as project duration, scope, location, and claim history must be considered. Working with insurance professionals can assist in minimizing expenses by customizing coverage plans to meet project-specific requirements.

Overhead costs

Analyzing past performance, projecting future costs, and distributing spending according to project complexity and duration are all part of the process of estimating overhead costs. These are the indirect expenses necessary for project execution but not directly attributable to labor, materials, or equipment.

Indirect costs

Miscellaneous expenses incurred during construction, including project management fees, subcontractor fees, and contingency reserves, are included in the category of indirect costs. Assessing any risks, uncertainties, and unanticipated expenses that can surface during project execution is a necessary step in the estimation of indirect costs. By setting aside a portion of the entire project cost as a contingency reserve, you can reduce the risk of unanticipated events and maintain financial stability during the building phase.

6. Finalize with profit and contingency

When calculating the total project cost, estimators will include a profit margin and contingency fund to account for unforeseen expenses and secure a profitable return on investment.

7. Never stop reviewing

Remember: Estimations are not static figures, but dynamic assessments that demand constant scrutiny and adjustment throughout the entire project life cycle. As the project progresses, unanticipated difficulties, shifts in the market, and changing needs can have a big influence on preliminary estimates. For this reason, it’s critical to keep an eye on things and to continuously review and improve expense estimates to make sure they reflect the realities of the project.

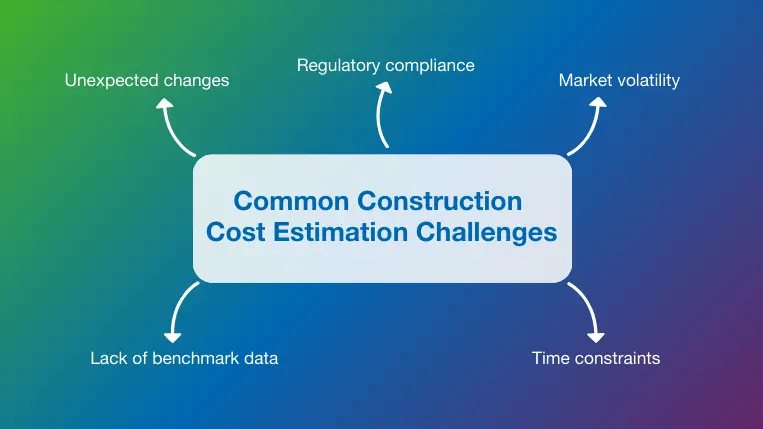

Common Construction Cost Estimation Challenges

Construction projects are known for their variation in scope, size, location, and duration, as well as the long list of additional factors that can drive expenses and cause overruns.

While this variation is part of what makes a career in the industry exciting, it can also lead to challenges when it comes to construction cost estimation. The factors leading to inaccurate estimates are well-known but often unavoidable as contractors and other stakeholders balance client demands with cost and quality control.

Reviewing and planning for these common obstacles as part of the risk management process is a good way to ensure their impact is not overlooked and that plans are in place to address challenges, even before they occur.

Unexpected changes

As the Greek philosopher Heraclitus said over 2500 years ago, “there is nothing permanent except change.” This is certainly true in the construction industry, where new client requests, additions, site conditions, design errors, and many other factors can lead to unexpected changes. These changes can present major construction cost estimation challenges, since the original information used to create an accurate estimate also feeds into the project budget, timeline, and expense reporting process.

Along with the construction contingency budgets created to accommodate unforeseen events and expenses, effective cost management practices improve transparency and collaboration while ensuring estimates are reviewed and adjusted as soon as possible. This helps to avoid unnecessary overruns and minimize delays and disputes.

Regulatory compliance

The costs associated with regulatory compliance include permitting fees, site inspections, consulting fees, and specialized labor. Since construction regulations change frequently or vary depending on the location, these factors can also impact the construction estimating process. Regulatory issues can also present problems when the requirements are not properly reviewed and scoped upfront, and changes to cost estimates occur late in the project to avoid fines or other non-compliance penalties.

Market volatility

As anyone who has ever worked in the construction industry knows, market volatility impacting material prices and availability, labor costs, and equipment operating expenses are always possible, and can sometimes occur with little warning. While this volatility is unavoidable, it can lead to serious construction project cost estimation challenges when estimates based on well-researched information and detailed quantity takeoffs suddenly become inaccurate.

Time constraints

Tight timelines are also common in this fast-paced industry, but time constraints can lead to estimating challenges, including errors based on rushed calculations, and overlooked details that may have a significant impact on costs.

Even when material cost databases, historical data, and software tools for analysis are available, time constraints can make it difficult to review all relevant specifications carefully, complete a site visit, and double-check calculations to ensure all information is complete and accurate.

Time constraints can also put pressure on contractors and subcontractors to submit construction proposals and bids without having time to adequately assess their material and labor costs.

Lack of benchmark data

Historical data from online databases, past bids, and other expert sources make it easier to establish benchmarks for comparison to new estimates, but these resources are not always available. Projects utilizing new design concepts or construction methods can be difficult to benchmark since they have no historical precedent for comparison. Other projects may lack the time or resources needed to complete benchmarking tasks adequately.

A lack of benchmark data can lead to cost estimation challenges, since it forces estimators to rely on less reliable (and less relevant) data, or make assumptions to fill in the gaps in information. Accurate and relevant benchmark data also helps to predict the safety, equipment, or compliance issues that might be encountered, which reduces the overall project risk.

What Can Construction Estimating Software Do for You?

For construction firms that want to produce accurate cost estimates to reduce waste and help improve profits, it’s a good idea to use construction estimation software to help you complete estimates quickly, accurately, and easily.

In most instances, the use of construction software will have a direct link to a procurement package. This link ensures that contractors purchase materials in line with the allowed rate and the allocated quantity. Any deviation from the cost estimate will then be flagged immediately to identify possible losses or buying gains.

But, it’s not just about streamlining the process. Estimating software helps to reduce the risk of human error, allowing for more precise and realistic results. This means that you can create more accurate estimates to help you win more bids.

Creating good estimates is an important factor in understanding the project’s commercial parameters and its ability to run smoothly. So, getting it done as fast and as accurately as possible is something that all contractors should strive for.

The ability to use historical data from previous estimates and have feedback from completed projects is vital to new estimates. By using reference projects and historical costs, you can estimate faster and more accurately. This is another major reason for using estimation software.

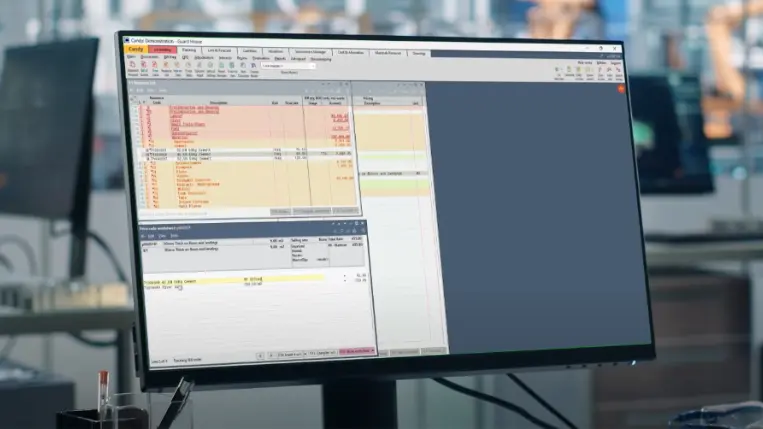

RIB Candy Streamlines the Cost Estimation Process

RIB Candy is our professional construction estimation software that assists contractors in producing efficient, reliable, accurate, and detailed estimates and quotes. With Candy, contractors can confidently and quickly produce reliable and competitive estimates and quotes to submit and win more bids. From on-screen construction takeoffs, estimating, and project planning to the final certificate, Candy targets the unique requirements of construction and engineering contractors in one exceptional project management solution.

The advanced features of RIB Candy are available through a single user interface that breaks down silos and helps project teams keep time and money aligned at all times. Valuable software functions that take construction teams to the next plateau of accuracy and efficiency include:

- An on-screen Quantity Takeoff (QTO) module capable of extracting precise quantity information from 2D drawings and compiling the bill of quantities (BoQ) electronically.

- A convenient Forecasting module integrated with the BoQ to support improved planning through the combination of the estimate, valuation data, and time schedule information.

- A Candy Cash Flow module to quickly analyze the financial impact of changes and variations in payment times, retentions, or closure dates.

- A Subcontractor Management module to provide rolling subcontract progress updates. This module supplies detailed information on subcontractor billing alongside other relevant cost, claim, contra-charge, material, and variation data.

Final Thoughts

At the beginning of any construction project, achieving an accurate cost estimation is vital. This will help manage the project’s scope ahead and allow all parties to understand their budget requirements. Good estimates are the first step to a great project, so getting it done right is very important.

Estimating software can help estimators gain a serious advantage. As results become more accurate, the process becomes easier, errors are reduced, and contractors can work with a more realistic budget.

Our professional construction estimating software, RIB Candy, offers innovative functionalities to take your estimating to the next level. If you are ready to benefit from efficient project control, book a demo today!

Most Recent

10 mins read

29 mins read

27 mins read

24 mins read

Blog Categories

Ebook