10 mins read

Understanding The Power Of Digital Construction Technology

The human race is currently experiencing the greatest period of transformation since the introduction of machine manufacturing in the 18th century. Driven by disruptive technologies and trends, this new era—known as the fourth industrial revolution—is impacting every aspect of the world. As a result, many industries have begun to harness digital solutions designed to give them a competitive edge.

Although the adoption of digital technology in construction has been slower when compared to industries like manufacturing and logistics, worldwide investment in digital construction technologies is expected to hit a record USD $30 billion by 2035. Despite annual investment growth of nearly 17%, the majority of construction companies still struggle to add value using digital tools. The reasons for this discrepancy include cost, complexity, and effort, but—in an industry notorious for running over time and budget—industry leaders are realizing the benefits of digital transformation in a big way.

In this blog post, we examine the benefits of digital construction, review construction technology examples, and share best practices for getting the most out of your digital journey.

What Is Digital Construction?

Digital construction involves applying digital technology to the design, planning, construction, and management processes. It incorporates a wide range of tools to automate tasks, improve communication, and enhance construction quality.

Digital construction takes on many forms, including:

- Simple messaging, collaboration, and document management systems

- Cloud-based construction enterprise resource planning (ERP) solutions

- Leading-edge software like 5D BIM (Building Information Modeling)

- Robotics and 3D printing technology

- Artificial intelligence (AI), drones, and digital twins

With project complexity and competition for work increasing hand in hand, adopting digital technology in construction provides a competitive advantage. It streamlines many design and construction processes that impact project schedules, budgets, and compliance while also improving communication and collaboration between clients, engineers, architects, and contractors.

The Key to Implementing Effective Digital Change

By collating data into one environment and making it accessible to all stakeholders across a project and business, digital construction empowers organizations with software designed to simulate events and test scenarios that will, and could, occur over the duration of a build. Digitizing and modelling a project in tandem with its physical construction not only enables transparent construction project collaboration but also improves decision-making and proactive change management.

For example, if a client decides to alter the design of a facade midway through a project, digital construction analysis allows you to anticipate the impact this change will have on the overall design, cost, and timing of the build. This provides you and your client with invaluable insights, in real time.

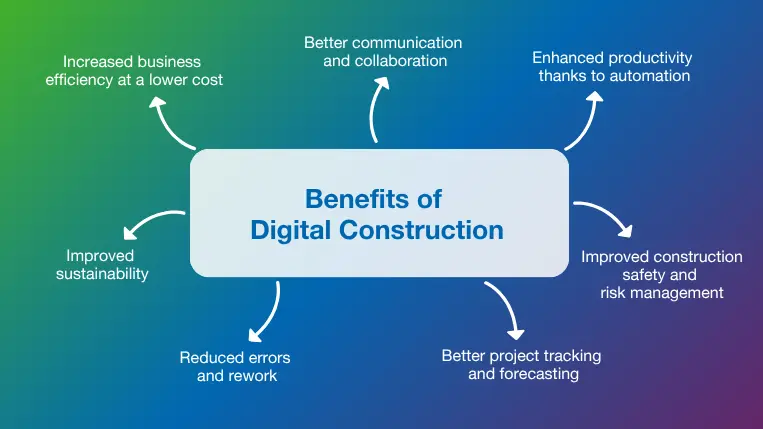

Benefits of Digital Construction

The shift towards construction digitization is owed to the many improvements in computer software and technology over the past two decades, and their direct applicability to the construction industry. Let’s explore some other benefits below!

Increased business efficiency at a lower cost

Construction costs have increased by over 40% since 2020, with everything from labor and materials to machinery and equipment experiencing ongoing cost increases. Digital construction methods help to offset these costs by improving productivity, automating resource planning, and reducing costly errors and waste. These efficiencies also allow construction project teams and contractors to take on more business in the same time span.

Better communication and collaboration

Most contractors, designers, and clients have already experienced how collaboration can lead directly to innovation, reduced confusion, and improved teamwork and morale. It should come as no surprise that the latest digital construction trends have steered the industry toward cloud based construction software that makes it easier for cross-functional teams to communicate and exchange information in real time. These digital capabilities are especially useful for virtual design teams spread out over multiple cities or countries.

Enhanced productivity thanks to automation

Like many other industries, gains in construction productivity often come from automating repetitive tasks so that human workers can focus on more challenging or creative issues. Digital construction tools continue to leverage automation to reduce wasted time and effort on processes such as scheduling, materials management, and quality control. As artificial intelligence and robotics improve, more automation will be applied to physical tasks like material and site inspections, concrete pouring, welding, and painting.

Improved construction safety and risk management

Improving job site safety and reducing risks are always top construction industry objectives. Wearable technology and equipment sensors are among the new digital construction technologies that provide early warnings for both workers and their team leaders. Improved construction communication tools, such as mobile apps and real-time messaging platforms, make it easier to report and correct safety issues quickly. Digital tools also improve risk management by enabling better identification, assessment, and mitigation of potential hazards before they impact the project.

Better project tracking and forecasting

Digital tools allow information to be collected and analyzed faster, which enables project managers to plan and schedule resources more effectively, detect problems or quality issues quickly, and track progress more accurately. Mobile-friendly software tools are key to real-time data transfer. Still, digital construction innovations like drones and Internet of Things (IoT) sensors also prevent information lags from slowing down progress.

This real-time information feeds into advanced forecasting methods that rely on centralized project data to identify trends and predict future labor, equipment, and material requirements. BIM software and digital twins are becoming valuable resources for both tracking and forecasting, with conditions in the field replicated in the digital realm throughout the project to provide a convenient platform for issue identification and predictive analytics.

Reduced errors and rework

Despite ongoing efforts to minimize design changes and improve the accuracy of construction specifications and drawings, 12% to 15% of all construction costs are still attributed to rework, which has a huge impact on project budgets and timelines. The combination of improved design accuracy, real-time communication, automation, and early issue detection brought by digital construction technology helps to prevent errors that can lead to costly rework and delays. As intelligent robots begin to take over error-prone and dangerous tasks, this will also free up workers to solve complex problems and communicate with other teams more effectively, so that errors are less likely to occur or go undetected.

Improved sustainability

Sustainable construction is much more than a passing trend, with designers, architects, and contractors all around the world recognizing the high demand for green building certifications like LEED or BREEAM, and the enhanced long-term value of sustainable structures. Digital technology in construction is an important piece of the puzzle, with multi-dimensional modeling tools like BIM helping to optimize material usage and energy efficiency while minimizing waste during construction and full operation.

Digital construction management software is another important element of sustainable building practices, with features and capabilities like embodied carbon calculations and lifecycle assessments allowing builders to reach their sustainability goals through informed design, documentation, and planning activities, while creating efficient and environmentally-friendly buildings that align with global demand.

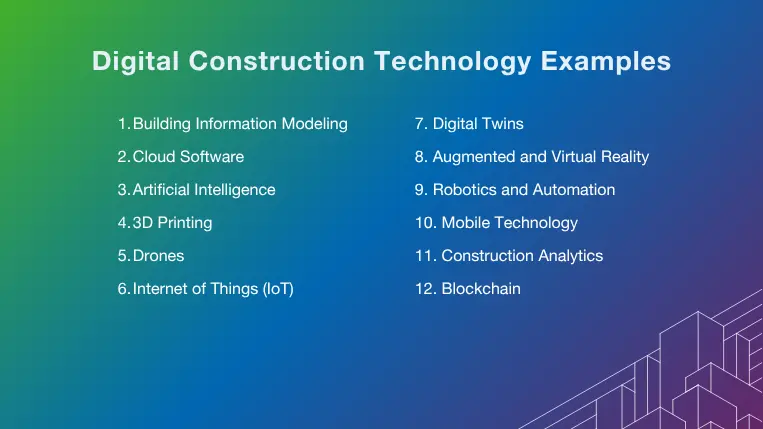

Digital Construction Technology Examples

Centralized construction management software that brings together data from many sources throughout the project lifecycle is the most obvious example of construction digitization. However, many additional innovations are now making their presence felt in the construction industry.

Building Information Modeling

Building Information Modeling (BIM) is a collaborative, software-based process that uses computer modeling to create digital representations of construction projects. BIM is used to support operations from the planning and design stages through construction project completion and forward into the operations phase in support of facilities management. Architects, engineers, and other stakeholders in different locations use BIM management software to work from a common platform in real-time while sharing new design ideas and modeling concepts digitally to minimize costly real-world testing.

Cloud Software

Digital construction management and construction estimating software are among the many construction solutions that are taken to the next level by cloud computing. The cloud provides a centralized data location with nearly limitless storage that is easily accessible by all stakeholders. Cloud computing is also a key enabler for new technologies like virtual reality (VR) and augmented reality (AR) that let contractors, architects, and clients tour a construction site without ever leaving their desks. If you want to learn more about this topic, check out our cloud computing challenges blog post.

Artificial Intelligence

Artificial intelligence (AI) is grabbing headlines as it develops to complete human tasks and interactions in remarkable ways. Applications for AI in construction range from design and bidding practices to transportation and asset management. Incorporating AI into BIM software platforms allows designers to generate unlimited options while instantly evaluating their design benefits and constraints. In addition, AI-powered robots are gradually moving from mundane inspection and monitoring to complex tasks and conditions that are too hazardous or physically taxing for human workers.

3D Printing

3D printing has become an important tool for designers in many fields as they quickly turn 3D models into real parts or prototypes. The 3D printing of materials like concrete and cinder blocks is one of the promising digital trends in construction that can also reduce costs and improve sustainability. Complex or customized parts can be fabricated more quickly with less wasted raw material and more design freedom. As technology improves, even materials like wood and metal can be 3D printed efficiently.

Drones

Drones are often used on construction projects to collect overhead images and create topographical maps. Along with energy, security, and agriculture, the construction industry stands to benefit immensely from drone technology as new applications continue to emerge. Drones can be used to monitor equipment positions and project status, ensure worker safety in remote or inaccessible parts of the job site, and complete inspections of large structures like towers and bridges.

Internet of Things (IoT)

The Internet of Things uses real-time sensors on (or within) everyday objects like equipment, tools, buildings, and even people to gather and analyze data sent back from any location. IoT is considered one of the foundational digital construction technologies, with uses like heavy equipment condition monitoring and predictive maintenance, embedded stress, strain, and temperature sensors in structures, and worker health and safety monitoring. Automated analysis of this data is the key to better decisions and productivity.

Digital Twins

Digital twins are complex digital replicas of physical things. They show us what is happening with a physical asset now while predicting what can or might happen to that asset in the future. Infrastructure like buildings, bridges, and highways are ideal candidates for digital twin technology. The twin integrates real-time data from IoT sensors and cameras to provide more insight into the construction project and allows construction managers, contractors, and clients in different locations to review a real-time replica of the project at any time.

Augmented and Virtual Reality

Virtual reality (VR) creates a completely simulated user environment, whereas augmented reality (AR) overlays digital information onto real-world images. The combination of virtual reality and detailed 3D models of construction projects allows designers, engineers, and clients to “tour” new buildings before they are even built. VR also provides a convenient way to train workers on equipment usage, jobsite safety, and other essential requirements.

Augmented reality is also a useful digital construction tool, since it enables safety or installation details to be shared with workers as they take on new tasks, and allows designers, builders, and architects to visualize interior or exterior changes in vivid detail, using the actual building as a backdrop. Both construction technology examples demonstrate how the merging of physical and digital realms continues to reshape the future of construction.

Robotics and Automation

Recent advances in robotics and automation have redefined industries, including manufacturing and agriculture, with robots able to perform tasks more efficiently and cost-effectively than humans, even in hazardous locations. As these digital construction technologies evolve, their impact will continue to be felt in the world of construction, with robots performing tasks like site cleaning, demolition, welding, and inspection safely and effectively.

Robotics will also be one of the keys to addressing chronic labor shortages in the construction industry in the years ahead, as automation is leveraged for repetitive and strenuous tasks, and human workers use their talents for more creative and productive pursuits.

Mobile Technology

Mobile apps and devices have changed the way we live, work, and communicate, and they are also becoming essential elements of digital construction. Mobile technology allows teams that are spread out across large construction sites to share safety alerts, status updates, photos, and other important information in real time.

Rather than continually dispersing paper construction blueprints to contractors and subcontractors each time a design or drawing change is required, mobile technology allows documents to be approved and distributed digitally, even while stakeholders are away from their computer terminals. Data collected in the field can also be fed back instantly, to keep project leaders informed on any damage, material issues, changes to site conditions, or new hazards.

Construction Analytics

The term construction analytics refers to the collection, processing, and analysis of various types of data to gain additional insights, improve planning and decision making, and optimize resource allocation. The data sources might include everything from project management and procurement software tools to drones, IoT sensors, and individual user devices.

Advanced algorithms are used to detect useful patterns and trends from what might otherwise seem like a disconnected web of data. Analyzing historical material, labor, and overhead costs can lead to more accurate estimates, while data on equipment repairs and utilization rates can be combined with onboard sensor data to establish predictive maintenance programs that reduce downtime and unnecessary equipment service.

Blockchain

Blockchain is a modern digital technology that allows multiple users to securely access the same information at the same time. The unique name comes from the blocks of information that are linked together to form a chain, with unique codes established to identify and protect the contents of each block. The security and versatility of blockchain technology complements the evolving digital construction workflow. Tamper-proof communication and storage systems are ideal for vital project documents, including contracts and financial records. Blockchain-based smart contracts support automated milestone tracking and payment processing, while creating a stable and secure audit trail of all activities and transactions.

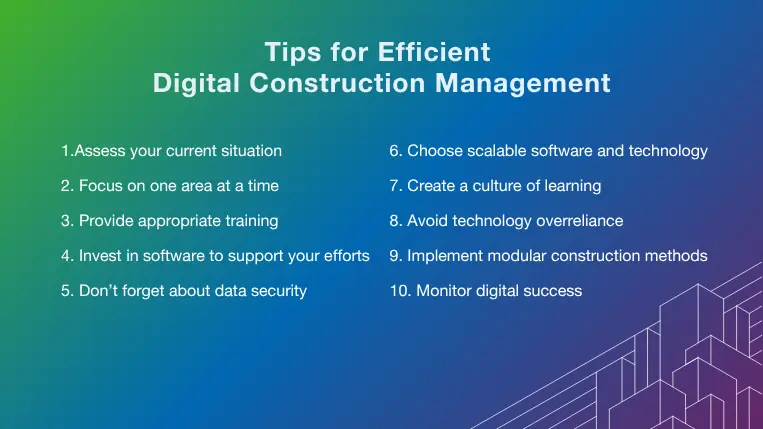

Tips for Efficient Digital Construction Management

No matter how powerful digital construction technologies are, their benefits are limited when they are not deployed or managed properly. Each digital tool has its own set of rules and best practices for safe and cost-effective use. Plotting your own digital construction course to success involves a methodical, step-by-step process.

Assess your current situation

Finding the right digital platforms for your situation means assessing the available technologies and deciding which will bring the highest return on investment (ROI) based on your gaps and opportunities. When evaluating digital construction tools, consider factors such as project size, complexity, and specific needs. Additionally, involving key stakeholders and technology experts in the decision-making process ensures that the selected technologies align with overall project goals and workflows.

Focus on one area at a time

There is something to be said for eating an elephant one bite at a time. Your organization’s future of digital construction can be a wholesale transformation that begins with tentative steps. For example, starting with construction management software will help your organization reduce inefficiencies, enhance communication, and ensure that all team members are on the same page. You can then expand on these benefits by investing in BIM software as you streamline the design process and explore other interactive IoT tools, drones, and robotics.

Provide appropriate training

All digital construction solutions require training for correct and optimized use. Every stakeholder should be trained to use software tools like BIM so they can fully benefit from the technology and collaborate effectively with other users. Physical assets like drones also require appropriate training, sometimes through a skilled third party, to ensure they are being deployed safely and in compliance with laws and regulations.

Invest in software to support your efforts

No matter what digital platforms you choose to use, software will form the hub of your modern digital operation, and your investment should reflect this importance. High-quality construction software can streamline workflows, enhance collaboration, and provide valuable construction analytics features and insight. It is also important to choose solutions that are scalable and adaptable to your projects’ evolving needs.

Don’t forget about data security

The digital platforms that are moving the construction industry into a new era are all about connectivity, but new endpoints, devices, and communication channels also increase hackers’ attack surface. Regular software updates, access controls, network monitoring, and antivirus are some of the IT tools that should be considered standard fare as construction moves into the digital realm. These solutions can prevent hacks, intercepts, and data breaches that can undermine digital technology benefits.

Choose scalable software and technology

As you review your current situation and invest in digital construction technology that can help your business right away, you should also consider your future needs and ensure the tools you select can grow with your business. For example, if you plan to support green building certifications, you should choose software capable of monitoring and reporting on sustainability metrics. Scalability also applies to the number of users, size of project, and data volumes you anticipate in the future, as digital construction practices begin to open new windows of opportunity. Planning for the next chapter can prevent costly software and infrastructure upgrades in the future.

Create a culture of learning

Training is essential when you bring new digital construction technologies into the fold, but the full benefits of new systems and software can only be realized when you create a culture of learning. This means transforming the business into one where everyone is interested in the latest trends and innovations, and finding ways to integrate them into everyday operations.

Business owners, construction project managers, and other leaders play a leading role in creating this culture by embracing technology themselves and demonstrating the benefits to their workers and colleagues. While training can help to clear some initial hurdles, mentoring and on-the-job experience also build digital construction momentum.

Avoid technology overreliance

The benefits of technology can be so apparent that many business leaders are ready to leap to full implementation, with no middle ground. It is important to remember that overreliance on technology can also introduce risks that can undo the potential benefits, so a methodical approach to adoption is best.

When construction companies rely on digital systems exclusively, they become more vulnerable to equipment malfunctions, data breaches, and other interruptions, and may lack the in-house skills needed to address technology issues quickly. A measured approach to implementation allows companies to address these personnel issues and develop risk management strategies that support a smooth transition.

Implement modular construction methods

One offshoot of digital construction that every company should consider is the use of modular construction methods, where building elements are strategically fabricated off-site to reduce waste, improve schedule performance, and control quality levels consistently. Advanced construction tools like BIM support modular construction by making it easier to model and test building segments and methods to find the most effective combinations. Complex machined or 3D printed elements can be tested, measured, and inspected in the factory so that any fit or structural issues are avoided. Digital tools also support the precise cost estimation and schedule planning activities needed to prevent a modular design approach from causing bottlenecks or delays.

Monitor digital success

Digital technology in construction is still gaining acceptance as traditional project management and design methods slowly fade into the background. Monitoring and publicizing the benefits of technology helps to overcome resistance to change and reinforces a culture of learning and innovation. When productivity gains, reduced rework and waste, and time savings are converted into real cost reduction figures, this allows everyone to see the positive return on investment (ROI) these digital tools can bring. Publicizing and rewarding these achievements is one of the best ways to increase support for the digital transition.

The Power of Digital Construction

When digital construction is implemented, even in its most basic form, it allows all parties involved to communicate and share data more proficiently for more efficient and cost-effective construction projects while enabling them to speak a common ‘digital language.’

With the economy in a potential downcycle, it may seem counterintuitive to invest in new technology now, but with the capacity available to focus on improving business processes, this may be the perfect opportunity to prepare for the future of the construction industry.

RIB Software provides a range of digital tools to establish a foundation for centralized data, automated processes, collaboration, and compliance management, which form the future of digital construction. A portfolio of innovative solutions, including RIB CostX for BIM takeoff, RIB BuildSmart for cost management, and RIB Candy for estimating, among many others, weaves a digital thread throughout every stage of the construction project lifecycle.

If you are ready to experience the power of digital construction for yourself, book a demo and try RIB Software Solutions today!

Most Recent

10 mins read

10 mins read

11 mins read

10 mins read

Blog Categories

Ebook