11 mins read

What is the Difference Between Construction Quality Assurance and Quality Control?

- Key Takeaways

- What is Construction Quality Assurance?

- Importance of Quality Assurance in Construction

- What is Construction Quality Control?

- Quality Control vs Quality Assurance: Key Differences

- Tips to Achieve Quality in Construction Projects

- What can Construction Quality Assurance Software do for You?

- Final Thoughts

Quality management is a fundamental part of a construction project. It ensures that the project’s end result is safe for operation, compliant with building codes, and meets the client’s initial expectations. To achieve all of this, it is fundamental for construction companies to collaborate to prevent misunderstandings that lead to costly reworks and delays.

Using modern construction software solutions to support different quality-related processes can present an important competitive advantage for organizations. Quality assurance (QA) and quality control (QC) are two activities that can be significantly improved with enhanced collaboration, real-time data, and reporting. However, no technological support will work if these processes are not correctly understood.

It is very common for construction professionals to define QA and QC as the same thing. However, while the two concepts are part of a successful quality management strategy, each has unique goals and requirements that must be followed. To help you avoid making the same mistake, we’ve put together this guide on quality control vs quality assurance and how both processes can be enhanced using the right software.

Key Takeaways

- Construction QA encompasses the systems, plans, and formal processes followed to ensure a high level of project quality, while quality control tools and practices are used to verify deliverables conform to specifications and client requirements.

- Quality assurance saves costs by preventing or detecting issues and defects well before the work is completed. This proactive approach also improves safety, compliance, productivity, and client satisfaction.

- While the objectives are closely related, quality assurance is the foundation of quality control. Construction QA specifies the project standards, while QC verifies that those standards are met. The subtle difference between QA and QC in construction results in different categories of metrics, quality tools, and responsibilities that span all project phases.

- Quality assurance plans, checklists, and interactive training programs are among the many useful tools that help to build a sustainable culture of quality on the jobsite.

- Cloud-based construction quality assurance software allows teams to establish and maintain QA tools, track important activities and data using interactive dashboards, and collaborate on key quality issues from anywhere.

Let’s dive in with some definitions!

What is Construction Quality Assurance?

Construction quality assurance (QA) is a systematic approach that defines the processes and systems to be followed to ensure the work in a construction project meets quality standards. Quality is defined by safety and legal regulations, and the client’s expectations.

ISO 9000 defines quality assurance as “part of quality management focused on providing confidence that quality requirements will be fulfilled.” In other words, construction quality assurance establishes operating procedures that result in a quality product. It involves planning and agreeing on standards that will serve as the foundation for how things must be done to meet the client’s quality expectations.

A good construction quality assurance plan ensures that projects are safer during construction and operation, comply with building codes and other regulations, and are less expensive due to better construction risk management. It also ensures that the building has long-term durability due to high-quality material and workmanship, resulting in high levels of customer satisfaction.

Some examples of quality assurance in construction include:

- Developing a construction quality assurance plan that outlines quality objectives, responsibilities, and requirements for materials, workmanship, and safety.

- Establishing evaluation criteria for suppliers to ensure they are compliant with quality standards from legal and client perspectives.

- Training workers and subcontractors about the quality assurance plan to ensure their work complies with internal and industry standards.

- Conducting regular inspections on the different methods, materials, and processes to ensure they still comply with quality requirements.

That said, having a QA strategy in place is not enough. To ensure quality management goals are achieved, monitoring and evaluating the work is necessary to identify issues, fix them, and achieve the expected results. That is where quality control comes into play.

Importance of Quality Assurance in Construction

Some people view construction quality assurance as just another set of rules and procedures that slow down progress and creativity, but the opposite is true. When all managers, contractors, and workers understand and implement QA plans and objectives, it allows them to work more confidently, knowing that systems are in place to prevent mistakes and defects or address them quickly. Some of the factors that make quality assurance for construction important include:

Issue prevention

The cost of quality principles teaches us how the cost of maintaining good quality is much lower when defects are found earlier or prevented altogether. For example, the cost of performing onsite audits or site inspections is minimal compared to the cost of correcting a major construction defect once a building is completed. Quality assurance in construction projects is intended to prevent issues like poor workmanship, material defects, cost overruns, and compliance issues that increase the cost of quality while decreasing customer confidence and satisfaction.

Improved productivity

The focus on training, early issue detection, and clear lines of communication that come with good QA practices also improve productivity on the jobsite. Many of the leading causes of poor productivity, such as design issues, equipment breakdowns, communication problems, and a lack of coordination, can be eliminated through a combination of proper planning and quality assurance.

Rework is another consistent drag on construction productivity and morale that QA practices help to reduce. Standardized procedures, regular inspections, and proper workforce training ensure worker knowledge is aligned with the latest quality standards.

Accident prevention

The building industry remains among the most dangerous for workers, with approximately 60,000 fatal accidents occurring each year. Quality assurance is closely aligned with safety on the jobsite, since serious issues like slips, falls from height, electrocution, and struck-by incidents often result from inadequate training, planning, or precautions.

Proactive construction risk management, adherence to standards, early detection and reporting of issues, and a focus on transparent communication are key elements of quality assurance in building construction that help improve safety and prevent injuries.

Regulatory compliance

Each construction quality assurance plan, procedure, or document is intended to standardize work and improve communication, and they are also created to ensure compliance with relevant building codes, safety standards, or legal requirements. Aligning all procedures and practices with standards like the Occupational Safety and Health Administration (OSHA) in the US, or the Health and Safety Executive (HSE) in the UK makes it easier to maintain regulatory compliance simply by following your own procedures consistently. Keeping an active database of relevant regulatory standards is another good way to improve compliance.

Customer satisfaction

The ultimate reason for quality assurance in construction projects is highly satisfied customers. Reducing defects, improving productivity, maintaining compliance, and preventing accidents and injuries all help to achieve this goal, while building a reputation for high quality throughout the industry.

The quality assurance definitions provided by ISO 9000 and other global entities echo this concept, since customers and clients are often the best judges of high quality, and their feedback (good or bad) is essential for setting appropriate standards and continuously improving.

What is Construction Quality Control?

Construction quality control (QC) is a set of processes and activities used to verify that project deliverables meet the client’s requirements and specifications. It involves monitoring and testing to identify issues and ensure quality standards are achieved.

ISO 9000 defines quality control as “part of quality management focused on fulfilling quality requirements.” It is a systematic approach to ensuring that construction activities, materials, and workmanship comply with the client’s expectations. Its main objective is to identify and correct issues during the construction stage through inspections, tests, and evaluations.

Some examples of construction quality control include:

- Conducting tests to ensure aspects like materials and dimensions meet the quality standards specified in the quality assurance plan for construction. For example, doing strength tests on concrete or checking the dimensions of beams and columns.

- Performing regular site inspections to identify any issues and rectify them before completion.

- Testing the completed work to verify its performance, safety, and compliance with quality requirements. This might include pressure testing of plumbing systems, electrical continuity, and HVAC performance tests.

Quality Control vs Quality Assurance: Key Differences

As mentioned, when speaking about quality management in construction, the concepts of quality assurance and quality control are sometimes used interchangeably. That said, while the two concepts describe processes and methods related to the quality of the product and how it meets customer expectations, how they arrive at that outcome is quite different. Understanding these differences can significantly impact the success of your quality strategies, as you’ll ensure each process is approached correctly.

Before discussing the differences, it is important to note that QA and QC can be defined differently from company to company. However, the universal understanding is that construction quality assurance serves as the foundation for the quality strategy. It provides the methods and specifies the standards to follow, while quality control verifies compliance with the standards and their accurate application.

Let’s explore QA vs QC in construction below!

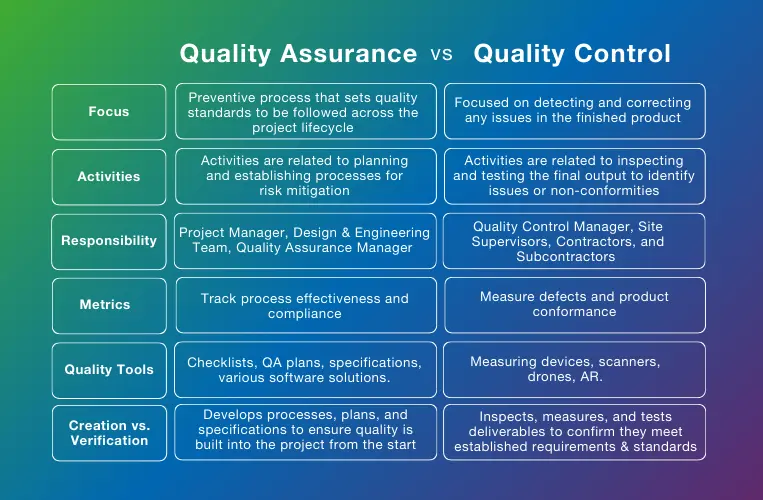

Focus

The first big difference between QA and QC in construction is their focus. Construction quality assurance is a preventive process that sets quality standards to be followed across the project lifecycle. It aims to continuously improve construction processes and methods to enhance the quality of the project. On the other hand, construction quality control focuses more on detecting and correcting any issues in the finished product that don’t comply with quality requirements. Its focus is to guarantee the finished work complies with what is stated in the QA plan.

Activities

Given the different focus, another difference is in the nature of the activities. The activities in QA are related to planning and establishing processes to mitigate the risks of errors or defects. Such activities include developing quality management plans with benchmarks and goals, implementing training programs, and reporting on progress, among others.

The activities in quality control for construction projects are less process-related and more about inspecting and testing the final output to identify issues or non-conformities. This includes conducting tests on materials, dimensional inspections, final product testing, and more.

It is important to note that while the activities in QA and QC are different, they complement each other. For example, the QC team is responsible for checking that the materials delivered by suppliers comply with quality standards. If any issues are encountered, the QA team is responsible for creating the procedures that the QC team must follow to correct the issue with the supplier and make sure quality is respected.

Responsibility

Another aspect that differentiates QA from QC is responsibility. Construction quality assurance is the management team’s responsibility, which can be represented by a quality assurance manager. In contrast, construction quality control is the responsibility of the quality control manager or quality inspector, who the general contractor often hires. The responsibilities are also different depending on the stage of the project.

- Preconstruction: During preconstruction planning, QA is more important than QC because, at this stage, the strategies to meet the client’s expectations are being developed. Once the design and specifications are done, the QC team can jump in and help engineers and architects develop solutions to meet quality standards.

- During construction: At this stage, the QA manager and their team will assemble useful documents for the contractor to guide their work. Once any construction part is completed, the QC team will conduct inspections and tests to see if the work meets the quality standards. If any errors are found, the construction team must fix them to comply with the requirements.

- After construction: Once all construction is complete, the QC team conducts a final inspection to make sure that every part of the building meets quality standards. If any changes are needed, the QA team generates documents and procedures to ensure the construction officials don’t make any corrections that reduce the quality of other structures.

Metrics

Quality assurance and quality control in construction both involve the tracking of metrics and the calculation of construction KPIs to assess progress and identify trends. Still, the metrics reviewed in each area are very different. QA metrics include things like process adherence, on-time training completion percentage, supplier performance, and the number of audit findings during a specific period or project.

QC metrics are more directly tied to inspection failure rates for construction tasks and materials, rework percentage rates, dimensional accuracy, and the mean time to repair (MTTR) after an issue has been detected. These metrics help to track ongoing team performance and provide insights into problematic design, material, or subcontractor choices that can be valuable for future projects.

Quality tools

Conversations related to construction often revolve around tools, but construction quality assurance brings together a different type of toolkit. Rather than hammers, saws, and screwdrivers, the managers and engineers implementing QA practices might utilize a quality assurance construction checklist, a QA plan, and detailed product specifications. Construction management software helps to put these documents and systems in place while ensuring everyone is trained in the latest versions.

Construction QC tools tend to be more physical in nature, with measuring instruments like levels and tape measures used to perform many routine quality checks, and specialized instruments like rebar locators, ground penetrating radar, and moisture meters used for specialized tasks. As the technology improves, tools like drones, augmented reality (AR) goggles, and robotic inspection equipment are providing a boost for inspectors and operators completing complex QC inspections.

Creation vs. verification

Another useful way to think of quality control vs. quality assurance in construction is through the division of creation (QA) vs. verification (QC). The QA process is all about putting new ideas and concepts on paper, then creating systems that will ensure they become reality. For example, during the design phase, a new sustainable building material specification might include unique ways to test a product when it arrives, or after construction.

On the other hand, verification practices are established to ensure that what has been planned and envisioned matches reality on the ground. A trained inspector measuring the strength or thermal performance of engineering hempcrete bricks is performing an important QC task. Green building rating systems like LEED also use test standards to evaluate factors like embodied carbon and volatile organic compounds (VOC).

Tips to Achieve Quality in Construction Projects

Managing quality in construction requires thoughtful planning and collaboration from all stakeholders. QA and QC are key components of a construction company’s overall quality strategy, but how do you start on the right foot? These tips will guide you!

Have clear “quality” definitions

Construction projects are collaborative efforts. Therefore, before you generate strategies, you should make sure to define what “quality” means to your organization and that the definition is clear for everyone. A good practice in this regard is to generate a document with the definitions and share it with every stakeholder to ensure a common understanding.

Set quality goals

Once that is out of the way, you can start setting quality goals to guide and evaluate your strategies. Your goals should be specific, measurable, realistic, and time-bound, such as reducing the number of defects or improving safety. Investing in a professional construction reporting system to track the progress of your goals and find improvement opportunities can present a big competitive advantage.

Involve everyone and define responsibilities

Communication and collaboration in construction projects are critical elements for success. To achieve a good communication flow, clear roles and responsibilities must be defined to ensure transparency and accountability in all quality-related activities. This means outlining each role with the related tasks and due dates and ensuring everyone knows who oversees what.

Create a quality control checklist

As mentioned earlier in the post, the QC team is responsible for inspecting the work carried out on-site. To make the process more efficient and prevent the risk of misinterpretations or errors, it is recommended to generate a quality control checklist that lists all critical aspects of quality management and what needs to be inspected or tested. Additionally, the list can also mention areas of concern or areas where quality is more important and should be noticed. It can also list the responsibilities of each construction team member to achieve accountability and transparency.

Develop a quality assurance plan

A QA plan is a comprehensive document that explains the quality objectives of a project, and how they will be met consistently. The plan provides a roadmap for everything from material handling and workmanship to safety and regulatory compliance, making it easy for everyone to understand the expectations. The plan should provide clear quality benchmarks and establish (or list) relevant procedures that explain how to meet these requirements. A plan for quality assurance in construction should also explain how monitoring, tracking, and auditing processes will be carried out.

Creating a detailed plan also provides an opportunity to list all relevant standards, procedures, and goals in one document, and share it with the client and all other stakeholders to ensure everyone is aligned.

Implement corrective actions promptly

Identifying errors, defects, and other quality issues is sometimes easier than correcting them. Cracks in walls or foundations can be relatively harmless, but they can also indicate more serious structural issues. The same applies to unexpected moisture and other quality issues that have many different causes.

Tracking all quality issues, even those that seem minor, is the first key to implementing corrective actions quickly. After the initial identification, standardized procedures for communication and remediation allow the proper stakeholders to evaluate the issues and decide what needs to be done. This might include further testing or root cause analysis to avoid addressing the symptoms instead of the underlying issues.

Review and analyze issues

Even with the best QA plan, it is very unlikely that no issues will be found during inspections. When issues are found, you should not just fix them and move on; a good project manager should analyze them to prevent them from happening again in a future project. A quality management strategy should be implemented at the company level, using what is learned from all projects. With each finalized work, expectations and quality requirements should be updated and communicated to everyone.

Make training interactive

One of the biggest quality mistakes companies in any industry can make is looking at training as a “check box” activity where workers are given content to read or watch with no personal interaction or examples they can relate to. Hands-on training is extremely useful for subjects like workplace safety and heavy equipment operation where workers demonstrate their knowledge using simulated events and scenarios.

A good training program should include real-world examples of quality assurance in construction and provide opportunities for trainees to interact with trainers, and one another, to make it more engaging and memorable. Follow-up sessions are also helpful to reinforce the original training, answer questions, and deliver any additional information that may be relevant.

Foster a quality culture

Building a strong culture is one of the best ways to safeguard quality assurance, since it helps to ingrain norms and habits that lead to high-quality results. Developing a quality culture on a construction site can be challenging, since each project involves a completely different scope and team, but there are many things that can be done to improve the culture over time.

Open communication channels, accountability, and a “safety first” mentality are values that should always be encouraged. Contractors, clients, and project managers help to build the culture when they lead by example or provide feedback on quality metric performance and celebrate success when quality goals are attained.

Use the right technology

Using the right technology to boost your quality strategies is a best practice that cannot be ignored. With the building industry suffering from productivity and communication issues, it is of the utmost importance to use technology to boost the efficiency of your strategies. At RIB Software, we offer a powerful toolkit of solutions that will help you boost construction communication and optimize your workflows thanks to automation and real-time data, which leads us to our next point!

What can Construction Quality Assurance Software do for You?

Do you work as a construction manager, contractor, or generally with quality assurance in construction? Then, you may also know the importance of keeping track of registration and documentation of the work done.

Defects and errors are often part of construction projects, and the ability to deal with them is crucial to a project’s success. Therefore, a good and effective tool is important to prevent errors and ensure that the chosen quality is maintained throughout the construction process.

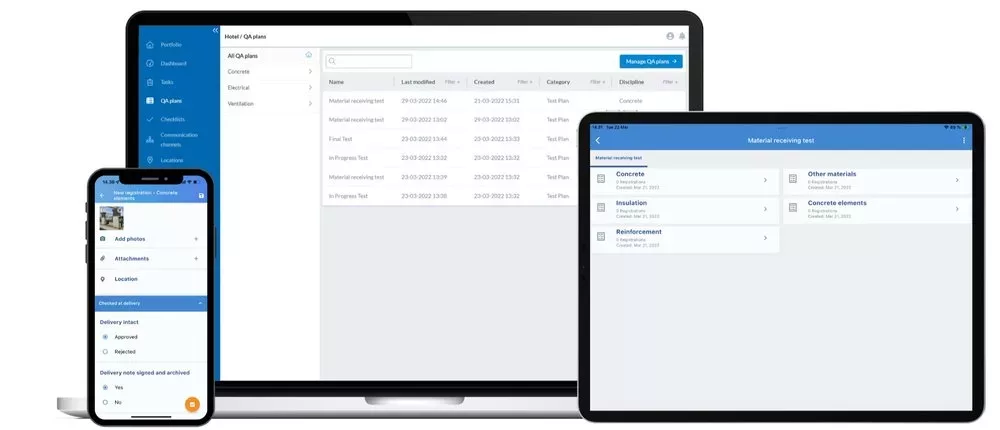

Our software, RIB Connex, provides the best conditions for correct and accurate QA. Read below about what our platform can do for your quality efforts!

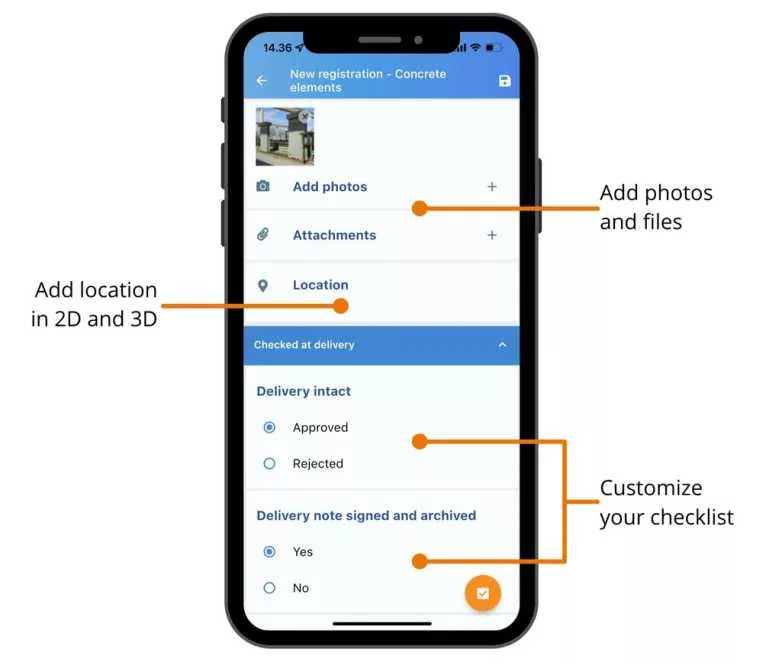

1) Create test plans for quality assurance easily

Use the customizable forms that best suit your company. With RIB Connex, you can easily create your own test plans with associated control schemes that can be adapted to all disciplines and processes, such as receiving, processing, and final inspection.

You can insert checkpoints yourself and describe exactly when (scope), how the control should occur (method, acceptance criteria), and what should be documented in connection with QA. Even smarter, you also have the option to link photo documentation and location to the checklists, making it even easier to ensure traceability and a well-documented basis.

Save time on your hard work and reuse the QA setup you’ve created in RIB Connex. You can easily duplicate plans and schemes or copy them to other projects you are working on. All your future projects are secured with a fast setup of QA processes.

2) View your checklists and tasks anytime, anywhere

Once all the QA plans are set up, you, as a contractor or supervisor, can simply take RIB Connex Mobile in your hand via mobile or tablet and collect registrations. All information is stored in the cloud, so it can be accessed, edited, or retrieved from anywhere – even when you’re offline. If you identify errors or challenges on site along the way, you can quickly create tasks directly in the 3D model or 2D plan and send them to the relevant project participants.

RIB Connex makes it easy to collaborate and communicate with internal and external parties on the project, ensuring that work is completed correctly and progresses on schedule.

If you’re unsure how far you’ve come, you can quickly get an overview of all the tasks you’re involved in by sorting and filtering in the columns to create exactly the overview you need. Nothing is missed, and errors and deficiencies are resolved faster.

3) Keep track of QA activities with project reporting and interactive dashboards

If you are responsible for QA and schedule compliance, having a clear overview of the QA process is essential—even when you’re not on site. RIB Connex helps you structure your QA plans and all related checklists in one unified system.

Through interactive dashboards, you can continuously gain valuable insight into how tasks and other critical issues affect project design, schedule, or finances from start to finish. This information allows you to make data-driven decisions based on real-time data.

With RIB Connex, you can also easily generate, share, and extract reports with tasks, registrations, locations, etc., and filter the reports with precisely the information you want to uncover. For example, you can view how many registrations are closed or active for a particular checklist to allocate the right resources.

Final Thoughts

As you learned throughout this post, understanding the differences and importance of quality control and quality assurance in construction projects can significantly enhance their success by mitigating errors, minimizing rework, and preventing costly delays. These two processes are fundamental pieces of a quality management strategy and must be developed in collaboration to achieve success.

Supporting yourself with the right technology is the best course of action to make the most out of your quality management strategies. RIB Connex is one of our professional construction management solutions designed by experts with decades of experience in the building industry. RIB Connex‘s quality management features make it possible to manage all inspections, QA plans, safety issues, and checklists with greater efficiency and positive outcomes.

If you are ready to benefit from state-of-the-art quality management, get a demo for RIB Connex today!

Most Recent

11 mins read

10 mins read

10 mins read

29 mins read

Blog Categories

Ebook