11 mins read

Understanding and Preventing Construction Site Accidents

Construction accidents are an ongoing concern for project managers, contractors, and clients. The combination of heavy machinery, unpredictable environmental conditions, and job sites bustling with activity make accidents unavoidable but not uncontrollable. Thankfully, many of the risk factors facing construction workers can be mitigated through a combination of technology and common sense. Understanding the primary types and causes of construction site accidents is the first step toward minimizing their severe consequences.

This RIB guide will tell you everything you need to know!

Construction Site Accident Statistics

Anyone who doubts the seriousness of accidents in construction needs to look no further than the annual statistics. In the U.S., over 1,000 construction professionals died on the job in 2022 alone, which is more than any other industry. This problem is not isolated to North America. The number of fatal construction accidents in the U.K. has risen by almost 20% over the last five years.

Statistics for non-fatal construction site accidents are also concerning, with incidences of falls, trips, and slips continuing to outpace the private industry overall. Additional U.S. statistics highlight the serious nature of accidents and their aftermath:

- 169,600 annual construction site injuries and illnesses

- 51% of construction workers are exposed to hazardous noise

- 4.5 million medically consulted injuries each year

- 25% of work-related injuries in construction go unreported

There may be better news on the horizon. An increased focus on technology, protective equipment, and workers’ mental and physical health can reduce the frequency and severity of construction-related accidents in the years ahead.

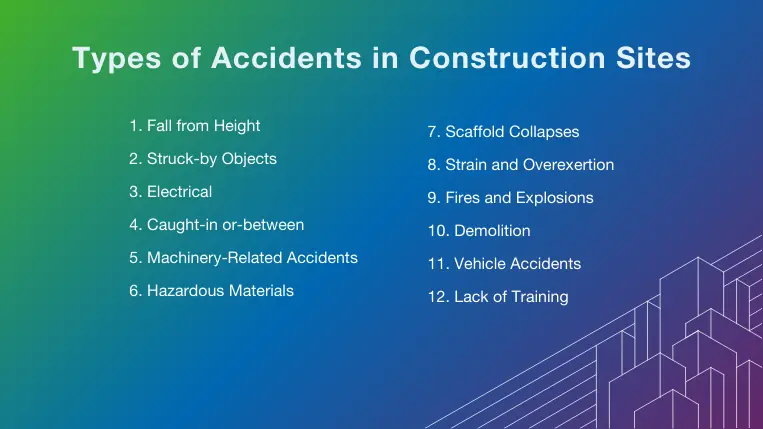

Types of Accidents in Construction Sites

Although there are dozens of accident types and risk factors impacting the construction industry, falls, struck-by accidents, electrocutions, and caught-in or between incidents have consistently ranked as the most common accident types. This has led OSHA to refer to them as the focus four, while others have dubbed them the “fatal four.” While these frequent accidents require ongoing focus and prevention measures, many additional construction accident types must be addressed.

1. Fall from Height

With many construction tasks performed on or around tall structures, it is no surprise that falls from height are consistently the most prevalent accident type in the construction industry. Falls can be caused by slippery conditions, unstable surfaces, improper safety measures, or some combination of these risk factors leading to overly dangerous conditions. Guardrails, safety nets, and fall prevention plans are among the tools available to protect workers from falls.

2. Struck-by Objects

Struck-by accidents involve workers being hit by moving objects, including falling materials, vehicles, machinery, or debris. The risk of struck-by incidents is heightened by the industry’s reliance on heavy equipment and large building materials frequently in motion. Guarding mechanisms, communication protocols, and a commitment to training help reduce these accidents’ frequency.

3. Electrical

Damaged insulation, exposed temporary power lines, and unsafe use of extension cords are among the many potential causes of electrical injuries. The impact of electrical accidents on workers can range from minor shocks to fatal electrocution. Recommended safe practices to prevent direct and indirect electrical contact include using caution and signage near energized lines, properly maintaining all electrical equipment, and de-energizing electrical wires and equipment before inspection and repair.

4. Caught-in or-between

The combination of heavy equipment, shifting materials, and collapsing structures can produce conditions where workers are suddenly caught, crushed, or trapped between two or more objects. This category also includes accidents where workers are injured while unsafely using a single piece of equipment. Training programs and safety protocols help to educate workers and protect them from this type of accident.

5. Machinery-Related Accidents

Excavators, cranes, bulldozers, and other industrial machinery used for construction can become dangerous sources of workplace accidents due to their immense power and size. Equipment malfunctions, improper use, or a lack of safety precautions can have an outsized impact. This makes safety protocols, equipment training, and lockout processes to avoid unauthorized equipment operation essential.

6. Hazardous Materials

Hazardous substances, such as gases, liquids, and dust particles, are common on construction sites. While some toxic substances are easy to spot and avoid, asbestos, odor-free solvents, and lead present less obvious risks that can be made worse by repeated exposure. These hazardous materials should be eliminated from construction projects whenever possible, and the appropriate personal protective equipment (PPE) should be used in cases when exposure can’t be avoided.

7. Scaffold Collapses

Scaffolding is an important part of the building industry, but it also presents hazards from tripping, falling objects, and complete collapses when scaffolding is not structurally adequate. Despite their temporary nature, care should be taken to build the scaffolding on secure ground, use only approved materials, and follow all recommended OSHA standards for scaffolding construction.

8. Strain and Overexertion

The outdoor conditions and strenuous work required for many construction jobs present risks that must be considered to prevent accidents, illnesses, and long-term health issues. Limiting exposure to extreme hot or cold weather conditions helps to avoid worker overexertion. At the same time, ergonomic tools, regular breaks, and automation help prevent repetitive strain injuries (RSI) caused by the ongoing performance of strenuous tasks.

9. Fires and Explosions

With welding equipment, flammable materials, and various fuel sources often used during construction projects, fires and explosions are other potential sources of construction site injuries and accidents. These hazards can worsen or spread quickly, which makes evacuation plans a must for avoiding burns and injuries from falling debris or destabilized structures.

10. Demolition

Like fires and explosions, improperly executed demolition processes can expose workers to falling objects, collapsing structures, and hazardous substances. Plans, procedures, and site surveys help to keep workers safe by maintaining safe distances and ensuring the spread of debris is controlled. OSHA regulations for demolition are intended to protect workers under these dangerous circumstances.

11. Vehicle Accidents

Large projects can become major traffic hubs with heavy equipment, worker vehicles, non-worker vehicles, and pedestrians all moving within the same limited space. Vehicle accidents and collisions are an ongoing concern that can be addressed through traffic management plans, clear signage, and designated crossing areas. Larger projects also invest in designated traffic control personnel to keep the environment safe.

12. Lack of Training

Proper employee training helps prevent or avoid construction accidents, no matter the cause. Safety training allows workers to identify and report dangerous situations faster while avoiding tasks that put them in harm’s way. Specialized training also helps workers understand the risks associated with different construction activities and how to mitigate them effectively while fostering a safety culture on construction sites.

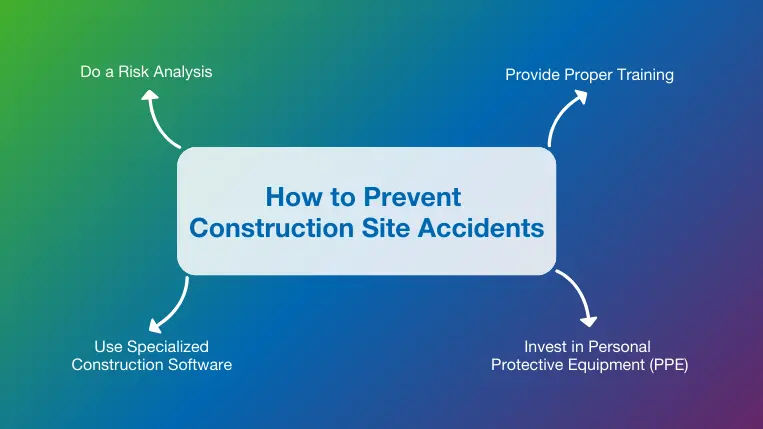

How to Prevent Construction Site Accidents

The list of causes, risk factors, and types of construction accidents is long. Still, a few basic precautions and practices can go a long way toward improving safety and creating a more positive and productive environment.

Do a Risk Analysis

Construction risk management is the process of systematically identifying project risks and their potential impact. This practice reduces costs and leads to more informed decision-making, but it is especially valuable for reducing accidents and improving overall project safety. The risk analysis process includes identifying and assessing safety risks early in the project so plans can be developed to mitigate or eliminate them.

Provide Proper Training

As one of the common threads required to address all types of accidents in construction, training should be tailored based on each worker’s native language, responsibilities, and exposure to dangerous conditions. Some of the best practices that prevent construction safety training from becoming a check-the-box activity with little long-term value include:

- Interactive training modules that incorporate real-life scenarios and decisions.

- Real-time feedback and active participation during training sessions.

- Digital construction tools like virtual reality to make training more realistic and immersive.

- Follow-up sessions to make sure information is followed and remembered.

Invest in Personal Protective Equipment (PPE)

PPE is another common thread that can reduce the impact of many construction hazards. Beyond the requisite hard hats, gloves, and steel-toe boots, each contractor and worker should understand what PPE is most appropriate for their specific tasks and environment. For example, Hi-Vis jackets or vests might be recommended for night work or high-traffic areas, while safety glasses should be standard in conditions where welding or flying debris might be present.

Use Specialized Construction Software

Communication and collaboration are additional keys to reducing construction site accidents and construction management software provides an ideal portal to capture and communicate information on potential hazards, safety protocols, and field incidents. Cloud-based construction software also makes it easier to manage and track training requirements, safety inspection schedules, and corrective actions that remove potential hazards. Mobile-friendly construction software ensures warnings and updates are communicated immediately.

Building information management (BIM) is another software tool that can dramatically improve safety and reduce accident rates. Digital representations of construction projects make it easier to detect defects and deficiencies that would lead to safety concerns if left uncorrected. BIM improves planning and coordination among dispersed teams, ensuring that safety measures are integrated throughout the project lifecycle. BIM also allows project teams to simulate various scenarios and assess the impact of safety strategies.

Construction Accidents: Final Thoughts

Preventing construction accidents is always priority number one. However, addressing the sources of accidents to improve worker safety, health, and job satisfaction can be complicated, with many accident types and risks. Fortunately, promising solutions are beginning to emerge. Construction software solutions simplify planning, communication, maintenance, and resource management while keeping the project focus squarely on job site safety. This combination of technology and awareness is the key to learning from the past to reduce accident rates in the future.

RIB provides an exceptional combination of construction software tools to improve efficiency, collaboration, and sustainability. Get a demo of RIB’s toolkit today and discover how state-of-the-art software solutions can transform your construction business!

Most Recent

11 mins read

10 mins read

10 mins read

29 mins read

Blog Categories

Ebook