11 mins read

Breaking Down the Top Construction Hazards with Mitigation Strategies

The combination of heavy equipment, volatile environmental conditions, and the dangerous activities inherent to construction make it one of the most hazardous industries in the world. Dangerous trades and tasks can also expose workers to construction hazards in the form of substances like asbestos, solvents, and inhalable dust particles. Anyone who works in the industry, including contractors, project managers, and clients, should understand the breadth and potential impact of construction industry hazards so they can take the necessary steps to protect themselves and others on the job site.

What are Construction Hazards?

Construction hazards are risk factors or dangers found at construction sites that can harm workers, equipment, or the environment. They include everything from safety issues like falls, fires, and explosions to extreme heat, viruses, and repetitive tasks.

Safety measures are required to mitigate equipment failures, harmful substances, and structural failures. Safety training, protocols, and technology can also be utilized to reduce many types of construction industry hazards. However, job sites can still be extremely dangerous, with approximately 20% of worker fatalities in the U.S. occurring in construction jobs despite representing just 6% of the workforce.

The early part of a construction worker’s career is more difficult since they may not be fully aware of the risks around them. Over 25% of all workers are injured at some point, but 60% of construction injuries occur within an employee’s first year.

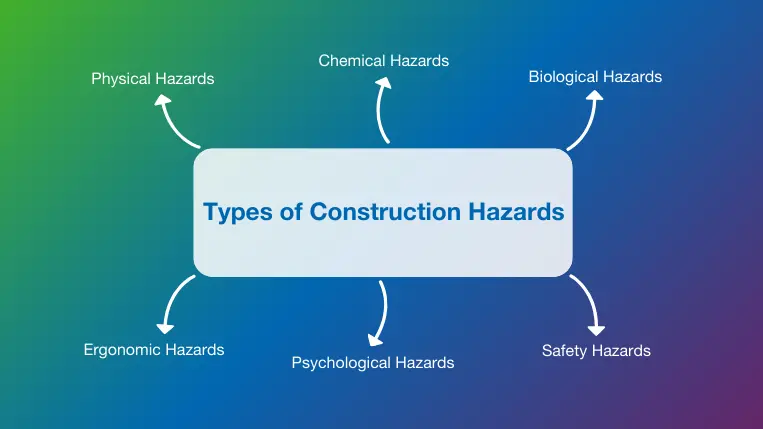

Types of Construction Hazards

Many common hazards in construction have existed for centuries, but new additions to the list continue to appear due to advances in digital construction technology, changes in building materials, evolving construction methods, and the increasing complexity of projects.

1. Physical Hazards

This category includes environmental factors that can potentially cause injury or otherwise impact worker health. Some of these are nearly unavoidable due to seasonal changes and extreme climates, while man-made physical hazards are more easily controlled or eliminated.

- Noise: Approximately 14% of all construction workers have experienced hearing difficulty. Jackhammers, bulldozers, and cranes are among the many noise sources contributing to hearing loss, stress, and fatigue. Noise-canceling headsets are a valuable tool to protect hearing without compromising situational awareness.

- Extreme temperatures: Record high and low temperatures have become familiar occurrences that indirectly contribute to construction site hazards. While cold temperatures create dangerous ice and slippery surfaces, excessive heat increases the risk of dehydration and heatstroke. OSHA recommends shortened workdays to mitigate heat-related hazards, especially for new employees.

- Radiation: Natural radiation is emitted from common building materials like granite, brick, and marble, while demolition and proximity to waste sites can expose workers to additional ionizing radiation. Monitoring radiation levels and issuing personal protective equipment (PPE) when appropriate can limit the harmful health effects.

- Vibration: Continued exposure to vibration from heavy equipment and power tools is among the hazards in the construction industry with potentially debilitating health consequences. Hand-arm vibration Syndrome (HAVS) is a chronic condition caused by exposure to vibration that can cause permanent loss of function and pain in the fingers. The Health and Safety Executive (HSE) estimates that approximately 17% of construction workers are at risk of developing HVAS.

2. Chemical Hazards

Hazardous substances, such as gases, liquids, and dust particles, are common on building sites. Many toxic materials are easy to recognize and avoid, while others may lack distinguishing odors or unusual appearances that serve as warning flags for workers.

- Hazardous materials: Substances like solvents, paints, and adhesives contain hazardous chemicals that can cause burns, eye damage, and other worker health issues, especially when stored improperly or spilled. Workers should be trained to review safety data sheets (SDS) that explain specific hazards and recommended handling practices.

- Airborne contaminants: Health hazards in construction sites also come from persistent dust in the air. This innocent-looking dust may contain harmful substances, including asbestos, lead, chromium (from steel), and silica (from bricks, concrete, and gravel), which can lead to various health issues. A recent study found that 38% of adults in the U.S. have been exposed to asbestos on the job. Recommended precautions include PPE and monitoring of the air to make sure particle counts stay within safe limits.

3. Biological Hazards

Biological health hazards in construction are caused by living organisms that occur almost everywhere but may be more common or concentrated on construction sites. This makes them especially dangerous since workers may be unknowingly exposed to biological hazards that blend in with their surroundings.

- Viruses and bacteria: Sites can be breeding grounds for viruses and bacteria. Stagnant water and contaminated soil can increase the spread of Legionnaires’ disease, tetanus, and respiratory infections.

- Animal waste: Site cleanliness and pest control practices should be closely monitored to prevent residual hazards in construction caused by rat infestations, bird droppings, or raw sewage. Exposure to these biological hazards can lead to severe health conditions, including Hepatitis and Weil’s disease.

Proper hygiene, PPE use, and rigorous health and safety protocols are crucial to mitigating biological hazard risks. A good construction risk management strategy can also help identify and mitigate these issues early on.

4. Safety Hazards

Safety hazards in construction are the leading cause of accidents and injuries due to unavoidable conditions in the industry. The four most common safety hazards (falls, struck-by accidents, caught-in/between, and electrocution) account for 65% of all construction fatalities and 40% of all nonfatal injuries.

- Falls: As the most common and dangerous of all construction hazards, falls can be caused by slippery conditions, unstable surfaces, or improper safety measures. A CPWR survey of construction workers found that over 48% reported no fall protection measures were deployed when they witnessed or experienced falls. Given these facts, safety inspections and training should be considered mandatory.

- Fires: Processes like welding and grinding and the presence of flammable gases and building materials make it hard to eliminate fire hazards on construction sites. Approximately 4,300 construction fires are reported each year. Evacuation plans and fire suppression systems help mitigate these dangerous risks.

- Explosions: The same risk factors that can lead to fires can also cause dangerous explosions, especially when pressurized containers contact live wires or other ignition sources. Safety precautions, including explosion-proof shields and other PPE recommended by OSHA, can prevent them from having devastating results.

- Caught in or between: Hazardous construction activities can lead to a worker getting caught, crushed, or otherwise injured between two or more objects. Heavy machinery operation, collapsing structures, shifting materials, and improper equipment use combine to create these dangerous scenarios. Guarding mechanisms, emergency communication protocols, high-visibility clothing, and a commitment to training are among the common steps to mitigate them.

- Electrocution: Electrical hazards can lead to injuries ranging from minor shocks and burns to fatal electrocution. Over 60% of all U.S. workplace electrocutions occur in the building industry. Live wires exposed during construction, buried power lines cut during excavation, and extension cords running through work areas must be handled carefully to avoid mishaps and accidents. This can be accomplished by inspecting for proper insulation, using appropriate grounding methods, and clearly marking and securing hazardous areas.

- Struck-by: As the name implies, struck-by hazards in construction are when workers are hit by moving objects, including vehicles, falling materials, swinging equipment, or debris. A survey of construction workers found that working around heavy equipment or vehicles and falling/flying objects were the two biggest causes of struck-by incidents. Precautions such as properly secured loads, safety barriers, and high-visibility clothing combine to reduce their impact.

- Equipment-related: Heavy equipment, machinery, and power tools round out the extensive list of hazards on a construction site. Comprehensive training and lockout procedures prevent equipment like bulldozers, cranes, and jackhammers from becoming sources of dangerous job site accidents.

5. Psychological Hazards

The building industry is not always associated with psychological hazards, even though they can lead to decreased performance and dangerous mistakes. A 2020 survey found that 83% of construction workers have experienced mental health issues. Personal conflicts, poor communication, and isolation are some effects of psychological hazards amplified by challenging working conditions.

- Stress: Even those with less physically demanding jobs may experience high-stress levels due to long hours, tight deadlines, and interpersonal challenges. Regular breaks, stress management programs, and technology to improve scheduling and collaboration in construction projects can go a long way toward reducing stress.

- Repetitive tasks: Construction work is known for its specialization, including repetitive tasks that can cause boredom, chronic pain, and job burnout that impact concentration and performance. Improved automation and robotics can minimize both hazardous and repetitive tasks so that workers can add value in more meaningful ways.

- Confined spaces: Plumbing, HVAC, and insulation tasks often involve tight spaces that can be socially and physically isolating for workers and create ventilation and emergency access challenges. Work rotations and breaks can minimize the psychological impact of these hazards.

6. Ergonomic Hazards

When identifying hazards on a construction site, it is important to consider ergonomic ones. These create dangerous conditions by putting too much strain on muscles and nerves over time and increasing the chances of injuries and accidents. Repetitive tasks are an example of an ergonomic hazard that can also become a psychological hazard when both the body and mind experience stress and fatigue.

- Improper workstation layout: An inefficient workstation layout can force workers into awkward postures or excessive reaching, leading to increased physical strain and potential for musculoskeletal injuries. These ergonomic factors should be considered early in the project to prevent prolonged strain and fatigue.

- Lifting heavy objects: Many of the materials and tools used in projects are too heavy to be lifted safely by one person. NIOSH specifies a weight limit of 51 pounds under ideal conditions, but many construction tasks require 100 pounds or more to be lifted or carried. Improper lifting techniques or lifting excessively heavy objects without appropriate mechanical aids can cause severe muscle strains, back injuries, and other long-term physical problems.

Construction Hazards: Final Thoughts

There is almost no limit to the types of hazards in construction sites today but keeping workers safe and productive is still possible with the coordination and the support of the right tools. The most common and dangerous construction hazards highlight the importance of regular inspections, training, PPE, and safety protocols as we mitigate and eliminate hazards to protect workers.

Construction tools make it easier to manage workers efficiently and quickly communicate information on construction hazards, while tracking the status of training, inspections, and timely corrections throughout the project lifecycle. As construction management, building information modeling (BIM), and construction business intelligence technology and software tools evolve, new strategies to address construction hazards and improve productivity arrive daily.

At RIB Software, we offer a professional and innovative toolkit of solutions tailored to address the needs of modern construction companies. Our solutions range from analytics to cost estimating and control, planning and scheduling, collaboration, and much more, making us a leading provider in the market. Get a free demo today and discover the transformative power of RIB software for yourself!

Most Recent

11 mins read

10 mins read

10 mins read

29 mins read

Blog Categories

Ebook