10 mins read

Exploring Digital Twins in Construction: Designing, Testing, and Building in a Virtual Space

The construction industry is undergoing a digital transformation with powerful technologies being adopted to improve productivity, efficiency and profitability. In that context, digital twins have emerged as one of the most valuable technologies of modern construction. Having a digital representation of objects from the real world, enables companies to simulate, analyze and optimize every aspect of a building’s lifecycle from design all the way to operation and maintenance, leading to increased efficiency and sustainability, reduced costs, and overall success.

This blog explores the topic of construction digital twins, offering definitions, advantages and challenges, tips, trends, and much more!

What are Digital Twins in Construction?

Digital twins in construction are virtual representations of physical objects, such as buildings, bridges, or entire cities, that use real-time data exchanges and advanced computer modeling to accurately simulate the behavior of their real-world counterparts.

Digital twin technology is useful for safely and efficiently designing, planning, and testing structures. It also supports effective monitoring and predictive maintenance activities throughout a building’s lifecycle.

Once a digital structure is established using 3D modeling technology, characteristics like stress loads and energy consumption can be captured and communicated from the real building using sensors, cameras, and survey data as the model is synchronized with reality.

Additional industries and professions that have embraced the benefits of digital twin technology include:

- Manufacturing operations that use twins to predict bottlenecks and improve productivity.

- Healthcare providers and medical researchers who study diseases using precise models of patient anatomy.

- Aircraft designers who test the feasibility of new concepts and changes virtually.

The components of a construction digital twin

A digital twin for construction is much more than just an accurate 3D model. Incorporating live data streams to mirror reality in virtual space is the key to on-demand testing, self-optimization, and unmatched visibility. The components of a digital twin that make this breakthrough possible include:

- Building Information Modeling (BIM): Multi-dimensional BIM models encode every specification, dimension, and material property within a highly detailed virtual platform that integrates real-time activity during and after construction. The BIM model forms the foundation for the digital twin building.

- Internet of Things (IoT): Real-time sensing using the Internet of Things (IoT) is the second important element of the digital twin, with everything from humidity and temperature to asset condition and location monitored continuously and transmitted back to the twin.

- Artificial Intelligence (AI): Machine learning and AI algorithms allow sensor data transferred to the BIM model to be converted into real-time insights on safety, maintenance, and performance. These capabilities also make advanced assessments of “what-if” scenarios possible during the design and construction phases.

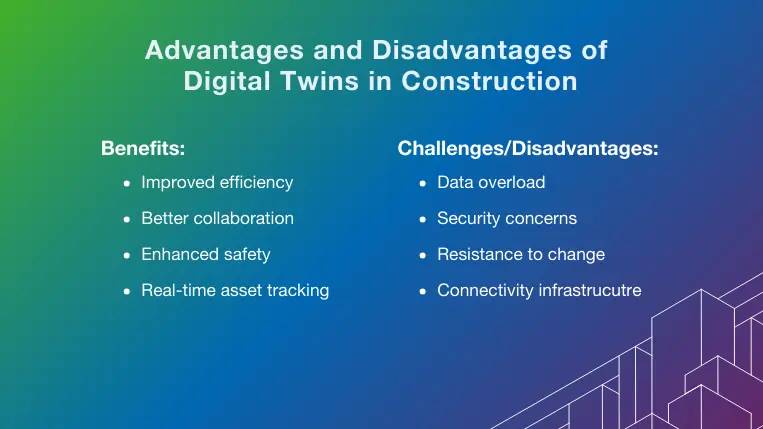

Advantages and Disadvantages of Digital Twins in Construction

Digital twin construction technology provides a long list of benefits that continues to grow as the applications and tools evolve. As with any advancement, there are also some challenges that must be addressed.

Advantages:

Improved efficiency

Testing design concepts and changes using a digital twin rather than an actual structure or physical model saves teams time and money from concept through project completion. As the digital twin lives on throughout the building’s active life, sensor data makes it easier to predict maintenance requirements, optimize electricity and water consumption, and test proposed building upgrades without disturbing occupants.

Better collaboration

A BIM digital twin breaks down silos between construction teams, designers, and construction architects by putting as much building information as possible onto a cloud-based platform that can be accessed from anywhere. With the status continually transferred from the field to the office, there is less chance of miscommunication.

Enhanced safety

Safety is an important byproduct of digital twin technology in construction, since unsafe conditions can be detected more efficiently based on data transferred to the twin. During the design phase, engineers use the digital twin to accurately test the impact of earthquakes, high winds, and other extreme weather events.

Real-time asset tracking

With an assist from the IoT, construction drones, and other monitoring and surveillance tools, the virtual model mirrors the conditions of the actual building, along with the machinery, materials, vehicles, and (sometimes) workers within it in real-time. This limits the need for physical monitoring and asset tracking activities and also makes resource allocation processes more efficient.

Challenges:

The shift to digital construction practices also brings issues and challenges that include:

Data overload

A building digital twin can become one small part of a system-wide twin spanning an entire city. This type of expansion can easily lead to data overload, with more data available than can be effectively stored or analyzed. This also makes it difficult to eliminate sources of data noise that impact decision-making and accuracy.

Security concerns

The ongoing connection between digital twins and physical structures can make them a target for attackers seeking to identify weaknesses or intercept data transmissions. Any implementation of digital twins in construction should include advanced cybersecurity solutions and access controls to guard against these attacks and threats.

Resistance to change

Construction software for planning, estimating, scheduling, and other important functions is quickly changing perceptions about the value of technology, but digital twins take this evolution to an even higher level. Limited implementation for small projects helps to break down resistance by demonstrating the benefits without fully detaching from traditional methods.

Connectivity infrastructure

Connectivity is what separates detailed BIM models and simulations from fully integrated digital twins for construction. Establishing a network of IoT sensors to turn static models into real-time twins can be a time-consuming and expensive prospect. To ensure accuracy and safety, this infrastructure must be fully installed and tested before launching the system.

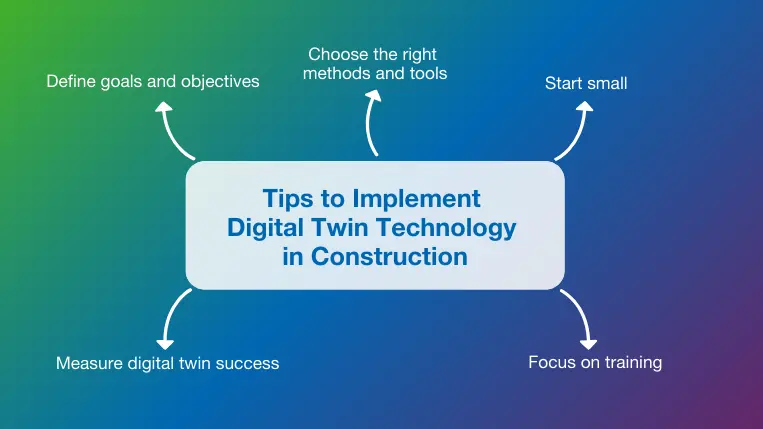

Top 5 Tips to Implement Digital Twin Technology in Construction

The digital twins construction companies need to become more efficient and easier to deploy with some thoughtful planning, preparation, and monitoring activities.

1. Define goals and objectives

The digital twin market is expected to grow by over 35% per year through 2030. Utilizing emerging technology is always a strong motivator, but the first step towards implementation should be deciding exactly what you want to achieve in design, safety, and collaboration improvements after deployment. These goals will allow you to scale your implementation and select the appropriate software and monitoring tools.

2. Choose the right methods and tools

There are many exceptional BIM digital twin options available on the open market, each with distinctive features, interfaces, and simulation capabilities. The software and hardware you select should be consistent with the implementation goals and objectives you established. This also applies to the IoT devices, construction drones, and other data capture products you select.

3. Start small

A good way to organically control costs, overcome resistance, and build expertise in digital twin construction is by implementing the technology on a limited basis, then ramping up slowly. Smaller construction project types with less complexity can be an ideal proving ground. This measured approach to implementation reduces the risk by allowing engineers and other stakeholders to level up their understanding before utilizing these tools on high-profile projects.

4. Focus on training

While hands-on experience is useful, there is no substitute for advanced training to help stakeholders master this technology quickly and learn from industry experts. Effective digital twin training methods include simulated projects that allow participants to complete workflows in a safe virtual environment, and instructor-led workshops and coaching programs where trainees learn from one another while getting advice from seasoned digital twin practitioners.

5. Measure digital twin success

To close the loop between your initial goals and objectives and successful implementation, you need to choose construction KPIs and metrics that allow you to measure the improvement. Positive trends in operational efficiency, downtime, rework percentage, and profit margin are some of the measurable benefits that should be expected. These tangible results also help to break down resistance by showing how valuable digital twins can be.

Real Success Stories of Digital Twins in Construction

One World Trade Center, New York, USA

The well-known building constructed near the remnants of its fallen predecessor was designed to withstand extreme winds, blast forces, and other shocks. At the same time, a compressed schedule made it essential for designers and architects to collaborate easily and test scenarios virtually. A building digital twin supported these objectives for the One World Trade Center project and continues to enhance the safety and efficiency of the tower over a decade after its opening.

Crossrail, London, UK

The Crossrail infrastructure project in London is a classic example of digital twin technology utilized to simultaneously overcome design, construction, and operational challenges. The Crossrail digital twin encompasses over 250,000 individual models that produce an accurate real-time representation. The advanced system improves railway visibility, efficiency, and safety through proactive electricity, water, and asset monitoring, along with continuous stress and strain feedback from tunnel walls.

The Future of Digital Twin Building Technology

Despite the growing list of success stories, digital twins in construction have only begun to reach their potential. As the market expands along with the adoption of IoT devices, cloud computing, and AI, the cost of digital twins will continue to drop. At the same time, new applications for smart buildings and cities around the world emerge.

With the expected boost in capacity brought by quantum computing and other innovations, large-scale digital twins will be instrumental in optimizing traffic, energy efficiency, and environmental management in urban areas. These advancements will also support the further adoption of 5D, 6D, and 7D BIM to integrate time, cost, sustainability, and facility management dimensions into digital twin solutions.

Final Thoughts

Digital twin technology has become one of the most exciting innovations in construction today, transforming how we design, build, and manage projects. Having a dynamic representation of a physical asset ensures stakeholders gain real-time visibility to support decision-making throughout the entire building lifecycle, reducing rework, improving collaboration, facility management, and sustainability.

At RIB Software we are committed to reshaping the future of the construction industry by developing innovative software solutions that assist companies around the world in all stages and processes, including planning, scheduling, procurement, BIM management, estimating, takeoff, and much more.

If you want to join the thousands of companies that trust us as their unique software partner, get your free demo for RIB’s toolkit today!

Most Recent

10 mins read

11 mins read

11 mins read

10 mins read

Blog Categories

Ebook