11 mins read

Complete Guide to Standard Brick Sizes and Types

Aside from the artisans who make their living forming, setting, and restoring bricks, most people rarely consider the history, size, and types of bricks we see all around us. Establishing standard brick sizes is part of a surprisingly interesting origin story that has shaped the construction industry and design practices for centuries. This guide to standard brick dimensions and types demystifies this important subject.

A Brief Introduction to Brick History

Ancient brick and stone structures like the Great Pyramids in Egypt and the Parthenon in Greece have stood for thousands of years, paving the way for millions of enduring brick structures. The ancient Romans, with their fired brick-making technology adapted from the ancient Greeks, spread their mass-produced bricks and mobile kilns throughout Europe.

These oversized ancient bricks bore little resemblance to today’s standard Roman bricks. Still, they set the stage for more traditional bricks after the empire’s fall, when they were commonly reused to compensate for a scarcity of building materials. By the time widespread brickmaking resumed in England in the 1380s, brick-making guilds and standards had been formed to help limit the variation in practices.

A per brick tax imposed by the British government in 1784 was another key turning point since builders increased their standard brick sizes to reduce their tax burden, just as the Industrial Revolution and machine-made bricks brought even more standardization. By the time the tax was lifted in 1850, many of the standard brick dimensions we know today began solidifying.

Why Brick Dimensions Matter

Even the earliest brick-makers understood why standard brick measurements were so important. Common brick sizes ensure consistency across different construction projects while making designing, planning, and building brick structures easier with minimized rework, waste, and structural issues. Designers and architects also need this consistency to ensure the aesthetics they want to achieve align with a standard brick size.

Standardized brick sizes also make it possible to mass-produce many popular types of bricks, lowering builders’ costs. When brick dimensions are predictable, workers can develop the skills and expertise required for the brick bonds (patterns) and mortar joints they are likely to see on multiple projects. Consistent and predictable materials also lead to more accurate construction budgeting and resource allocation.

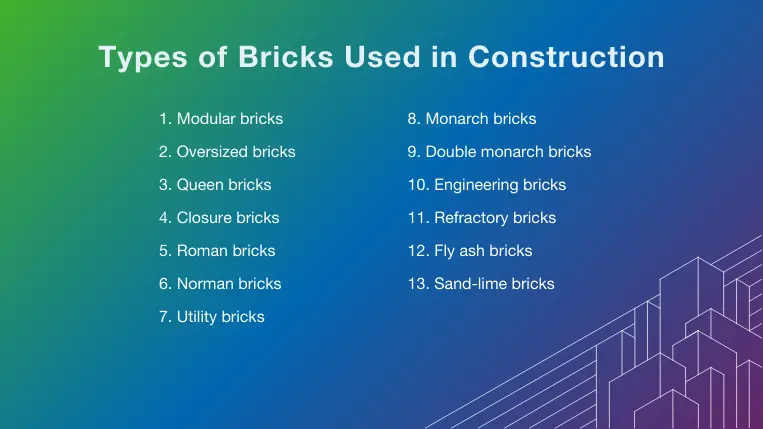

Types of Bricks Used in Construction

Over the years, many types of bricks have evolved, each offering features and dimensions to suit specific construction projects. Like most other construction materials, bricks are available in various colors and materials, which impacts their cost. The various brick categories often complement each other when used together to create structural and visual contrasts.

- Modular bricks: As the name implies, modular bricks are standard-sized bricks designed for easy layout, construction, and installation. Although they come in many different styles, all modular bricks have a standard length equal to 2 times the width plus a single mortar joint.

- Oversized bricks: With more brick surface area to work with, oversized bricks carry the legacy of ancient builders into the modern age. Non-standard oversized bricks also improve structural strength and speed up construction by reducing the overall brick quantity.

- Queen bricks: These large, non-modular bricks have a square core that allows mortar to flow through them more easily. With a narrower (2-13/16”) width and a larger face, queen bricks are also lighter than traditional bricks, even though fewer are needed to build or face a wall.

- Closure bricks: This type of brick serves an important purpose by filling in gaps or creating corners where a standard-size brick would not work. Masonry experts often cut these bricks to size at the job site to ensure the project’s aesthetic appeal.

- Roman bricks: Much has changed since the first Roman bricks, which were sometimes up to 24” (610mm) in length, were first produced, but they have retained their distinctive flat and slender profile and unique appearance, which is still popular today.

- Norman bricks: These bricks get their name from the Romanesque architectural style in Europe around 1,000 years ago, which featured sturdy walls and decorative trims. A Norman brick is also slender and flat, although slightly thicker than a Roman brick.

- Utility bricks: Modular utility bricks with five open cores are popular for landscaping, paving, and many other types of construction. With an equivalent height and width, utility bricks are efficient for stacking and aligning into various building forms.

- Monarch bricks: Also known as meridian bricks, these oversized modular bricks are both taller and longer than traditional red construction bricks. This standard brick size creates a bold and durable look, especially for the exterior walls of large buildings.

- Double monarch bricks: These bricks are identical to standard monarch bricks but twice as tall (8”/ 203mm). They are also called hollow bricks because over 25% of their interior structure consists of hollow round cores that reduce their weight and make them easier to reinforce.

- Engineering bricks: This high-quality brick type is made with construction considerations like load bearing and water resistance in mind rather than aesthetics. Engineering bricks can be made of heat-treated clay, but some are made of concrete. Engineering brick dimensions are usually similar to standard brick dimensions.

- Refractory bricks: This brick category is also known as firebricks since they are designed to withstand extreme heat in places like furnaces, kilns, and other high-temperature enclosures. The brick size for refractories varies depending on the application and requirements.

- Fly ash bricks: These environmentally friendly bricks are made from fly ash, a byproduct of coal burning, along with sand, lime, and gypsum. Their composition also makes them a lightweight and durable alternative to traditional red clay bricks.

- Sand-lime bricks: Another brick made from unconventional materials is the sand-lime brick, also known as the calcium silicate brick. With a sand content of 88% – 92%, these bricks are easy to manufacture from naturally abundant raw materials and are known for their sharp, clean edges and high compressive strength. However, they are not water or fire-resistant.

Standard Brick Sizes and Dimensions Around the World

The standard size of a brick has not changed much over the past 100 years, but the answer to the question: “How big is a standard brick?” varies depending on where you are in the world. Understanding these variations helps designers, architects, contractors, and brick masons adapt to the unique building practices of each country.

- Standard brick size UK: British standards have called for a brick size of 215mm long x 102.5 wide x 65mm high since the metric measurement convention was adopted in 1970. The length of a standard UK brick is precisely twice the width, with one standard 10mm mortar joint between bricks. This symmetry makes it easier to vary brick orientation within a wall or structure.

- Standard brick size USA: Not surprisingly, the common brick size in the USA, still following the imperial (inch) standard, differs slightly from the UK size. A standard-size brick in the USA is 8” x 3-5/8” x 2-1/4” (203mm × 92mm × 57 mm). These smaller modular bricks also remain symmetrical during construction.

- Standard brick size ZA: Standard brick measurements in South Africa have also diverged somewhat from the UK, although they have grown larger instead of smaller. The most commonly used modular bricks in South Africa measure 222mm x 106mm x 73mm.

- Standard brick size UAE: Due to regional climate and construction practices, very large concrete bricks are quite popular in the United Arab Emirates. The size of a standard brick in the UK (215mm x 102.5mm x 65mm) is followed when conventional clay bricks are used.

- Standard brick size AU: Design trends, construction efficiency, and a warmer climate have combined to make brick sizes in Australia grow slightly larger, with standard Australian brick dimensions of 230mm x 110mm x 76mm.

What Can Construction Estimating Software Do for You?

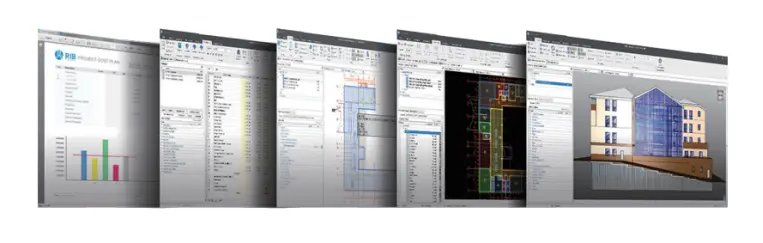

Accurate material and labor projections are essential throughout the construction bidding, planning, and execution phases of a project. Large construction projects with millions of bricks in various sizes, types, and price ranges highlight the need for powerful construction estimating and takeoff software to ensure bricks are counted correctly and avoid costly mistakes.

Our powerful software RIB CostX facilitates accurate quantity takeoff and estimating for bricks and other common construction materials, with the features and functionality needed to complete takeoff from 2D drawing files, 3D BIM models, and other common design file formats. The powerful functionalities provided by our platform allow users to automatically take off quantities from drawings to ensure project resources are spent smartly. Even better, quantities automatically update if any changes are made to the design, making it a reliable partner for accurate and efficient estimating.

Final Thoughts

As construction practices have evolved over the centuries, projects that once took decades can now be completed in years or months. The standardization of common materials like bricks has played a key role, making it easier to render designs that transfer to the real world with less customization and rework.

State-of-the-art platforms like our powerful estimating and BIM takeoff software, RIB CostX, take the benefits of standardization to the next level, deploying advanced analytical and computing tools to pinpoint material requirements earlier and more accurately. If you are ready to take control of your takeoff and estimation practices, get a free demo of RIB CostX today!

Most Recent

11 mins read

11 mins read

10 mins read

10 mins read

Blog Categories

Ebook