4 mins read

Thinking Spatially And Modeling In Five Dimensions

9 mins read

“With the 5D planning with iTWO, we now have the opportunity to save time on the parts of a project that require intensive calculation, so that we can reinvest it exactly where it is most important.”

Thomas von Küstenfeld

Digital Building Models as a Basis

The HENN office, with its locations in Munich, Berlin and Beijing, can look back on more than 300 successful projects. The office plans demanding construction projects for more than 100 clients worldwide, with a particular focus on the automotive industry and commercial and scientific buildings. With the Autostadt in Wolfsburg, the Transparent Factory for Volkswagen in Dresden or the Innovation Center for pharmaceutical company Merck in Darmstadt, the office has made a name for itself not only in Germany. In the Chinese province of Hainan, HENN was responsible for the planning of the 450-meter high Haikou Towers, currently under construction. Many larger projects are planned at HENN using a digital data model of the building. Here, the 3D CAD software Revit from Autodesk and iTWO 5D from RIB are used to integrate the 3D model with the costs in a completely continuous process.

On behalf of the Munich State Building Authority II, the office is currently planning the new Faculty of Electrical and Computer Engineering of the Technical University of Munich, located in Garching. Here, four buildings are being constructed on a plot of approx. 20,000 square meters in two stages. They are surrounded by a glass shell, creating space for two large auditorium. In the first stage, five research facilities for employees of the university and students will be erected. In stage 2, the “High voltage” hall will be created, one of them taking on the function of a “lighthouse” for the entire new project. HENN won the competition to carry out the extensions and new-builds on one of the largest research campuses in Europe in 2014. The first stage, conceived on the basis of new, digital planning processes, is currently in service phase 5.

Partially Automated Quantity Determination

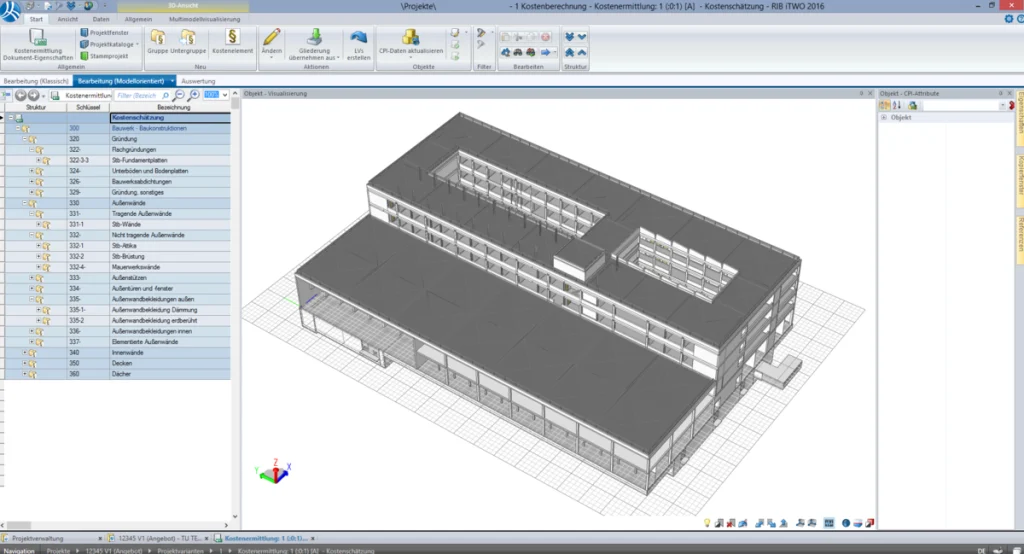

In 4D or 5D projects like these, the planners create a model in the 3D CAD system in service phase 3, forming the basis for a cost model in the RIB software iTWO 5D. 4D or 5D planning means integrating a graphic 3D model throughout with costs and/or time information from a schedule. When the graphic 3D model has been created, specific, defined information is added by the company. It can then be transferred in full into the RIB system. The quantity determination and evaluation of attributes in iTWO 5D takes place partly automatically. For all objects that are not yet linked with costs in this early service phase, price research first takes place in the company-internal price database. If these are new elements, not yet used in this form, the office will initiate contact with component manufacturers or construction companies to determine a price calculation.

On behalf of the Munich State Building Authority II, the office is currently planning the new Faculty of Electrical and Computer Engineering of the Technical University of Munich, located in Garching.

Interior view, new-built Faculty for Electrical and Computer Engineering, Technical University of Munich. The first stage of construction is currently in service phase 5.

Model-based cost determination with RIB iTWO 5D. Clearly it is not just the optimization of a partial process, such as quantity calculation, that is important to the architects at HENN, but also the realization of the design within the cost range approved by the client.

Control Mechanisms Are Essential

For this reason, it is important to carry out result monitoring in the iTWO software in this regard

Thomas von Küstenfeld

Where, earlier, measurements had to be created manually, the quantities in this integrated planning method are directly transferred from the geometric model. This means, on one hand, that the quantity calculation takes place partly automatically, but also means that the planners interact less intensively with the quantities and do not always recognize errors immediately. “For this reason, it is important to carry out result monitoring in the iTWO software in this regard,” explains Thomas von Küstenfeld, who is responsible for digitalization at the HENN office. The results are checked, validated and comparison values are generated in order to exclude the possibility of error, especially in more complex planning. Accuracy is also required for all objects that are not yet present in the model at this early stage. These must, for example, be derived from room perimeters or volumes and are available after this point for cost determination.

Embarking on New Paths

Until this process became standard, the planners at HENN had to try out completely new ways of doing things. This took patience. Ideas for the digital process that were put to test practically in the course of an initial, medium-size pilot project turned out to offer little chance of success. “The biggest challenge for us with the entire 5D process was thinking practically entirely from back to front,” Küstenfeld emphasizes. “What this is about is the way values like quantities or unit prices can be determined digitally from the model, and that in an early phase. This was somewhat unusual for our colleagues in the office,” he adds.

Thanks to comprehensive support from the software manufacturer RIB throughout the entire course of implementation, the planners were introduced project-by-project to the new methods of digital planning. “Working together with RIB helped us decisively in taking these new paths,” Thomas von Küstenfeld remembers. “If the practical application showed that certain situations couldn’t be solved, remedy was often given in new versions of the program and we could move our thinking a step forward again.”

Design and Precise Costs in Focus

In the meantime, the new process has become established in the company and even more advantages are becoming evident. First, while a lot of effort is shifted to the start of a service phase in model-oriented planning, it is reduced in other areas, so that digital cost planning ought not to mean extra labor for the employees of the office. “With the 5D planning with iTWO, we now have the opportunity to save time on the computationally intensive parts of a project so that we can reinvest it exactly where it is most important ”, explains Küstenfeld. And clearly it is not just the optimization of a partial process, such as quantity calculation, that is important to the architects at HENN, but also the realization of the design with in the cost range approved by the client, as Küstenfeld emphasizes. Further time is allotted to deal with precision in costs, as in this area it is possible now to request quotes from additional manufacturers and thus offer the client alternatives.

Reduced It Interfaces

Thomas von Küstenfeld is convinced that working with a 3D model matches the spatial thinking of an architect and thus represents the natural extension of previous planning methods. “Digital planning offers added values in many places,” the architect and head of digitalization at HENN acknowledges. “Starting from a digital model we can, for example, use Virtual Reality for presentation purposes or create a physical model through 3D printing.” Great advantages are above all also conferred by being able to create an unbroken, thoroughgoing process using the 5D method. Because whenever there are changes to the planning, the model is updated with new quantities, reducing the risk of error. “Thanks to iTWO 5D, we have been able to reduce our IT structure from five to three software programs. This means fewer interfaces, increased security and last but not least greater user comfort,” von Küstenfeld concludes.

Benefits for HENN:

- High transparency in the planning process

- Improved coordination of all involved in planning

- BIM as an all-encompassing method ensures quality in the project

TESTIMONIAL REPORT AS DOWNLOAD

Most Recent

4 mins read

3 mins read

3 mins read

4 mins read

Case Study Categories

E-BOOK